Product Series

Pulverization of active pharmaceutical ingredients(APIs),including hard,crystalline,and fibrous materials,as well as materials requiring very fine particle size.

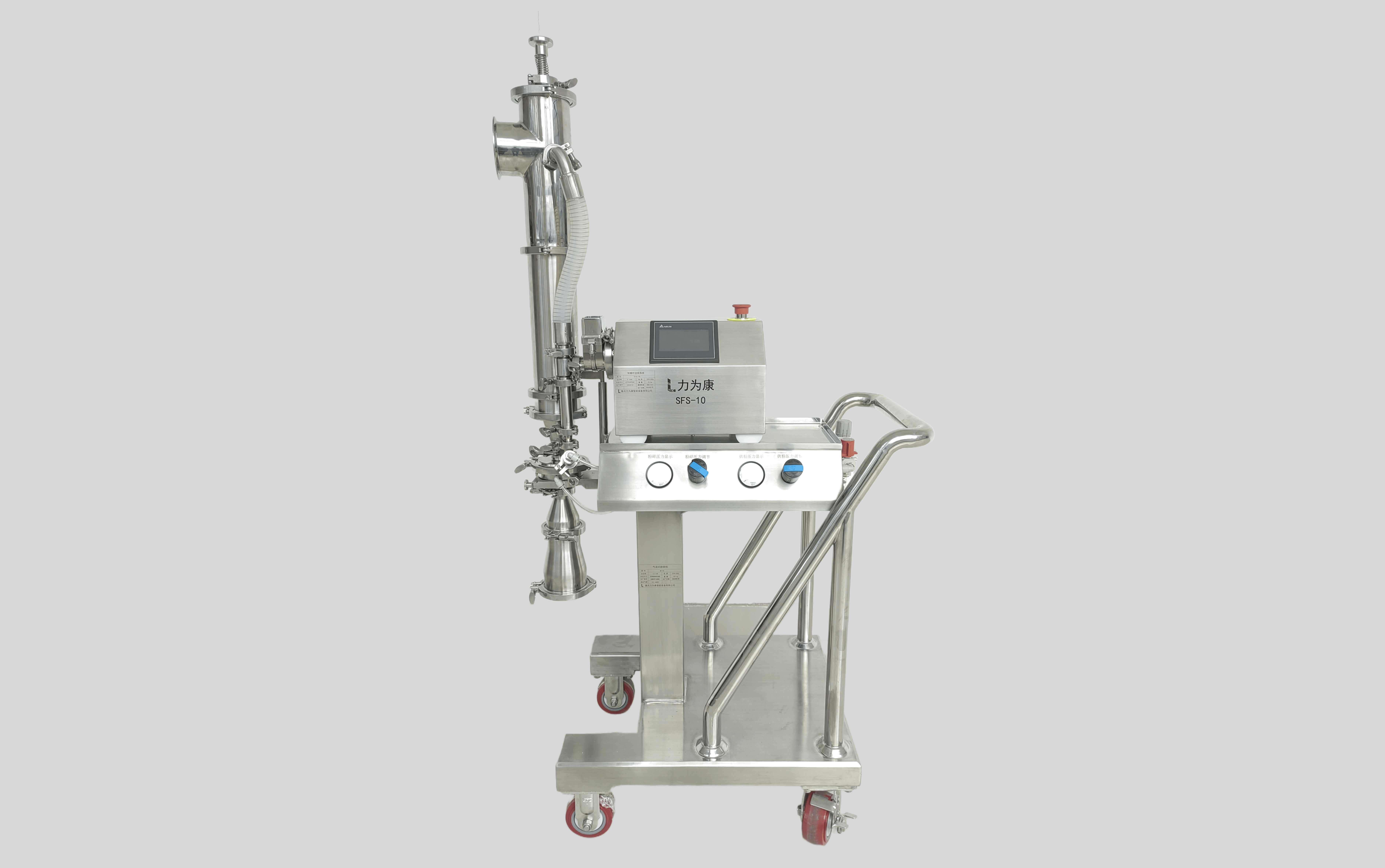

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

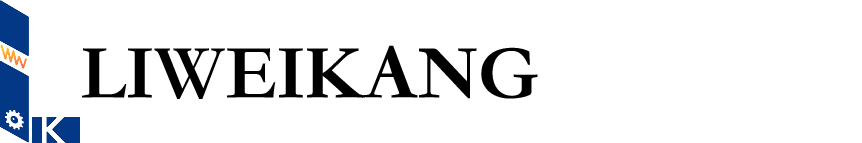

Chongqing Liweikang's self-designed whole grain machine's right-angle transmission system and shaft sealing technology greatly reduces the risk of material contamination.

Suitable for dry ultrafine grinding of various brittle, crystalline, thermosensitive, and low to medium hardness materials. Applied in industries such as chemical, pharmaceutical, and food, it has high efficiency and no dust leakage.

Electric lifting cone mill(ZLJ-208-Y)

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

Three types of whole-grain knives: round whole-grain knife, square whole-grain knife, and toothed whole-grain knife, suitable for various materials with different properties.

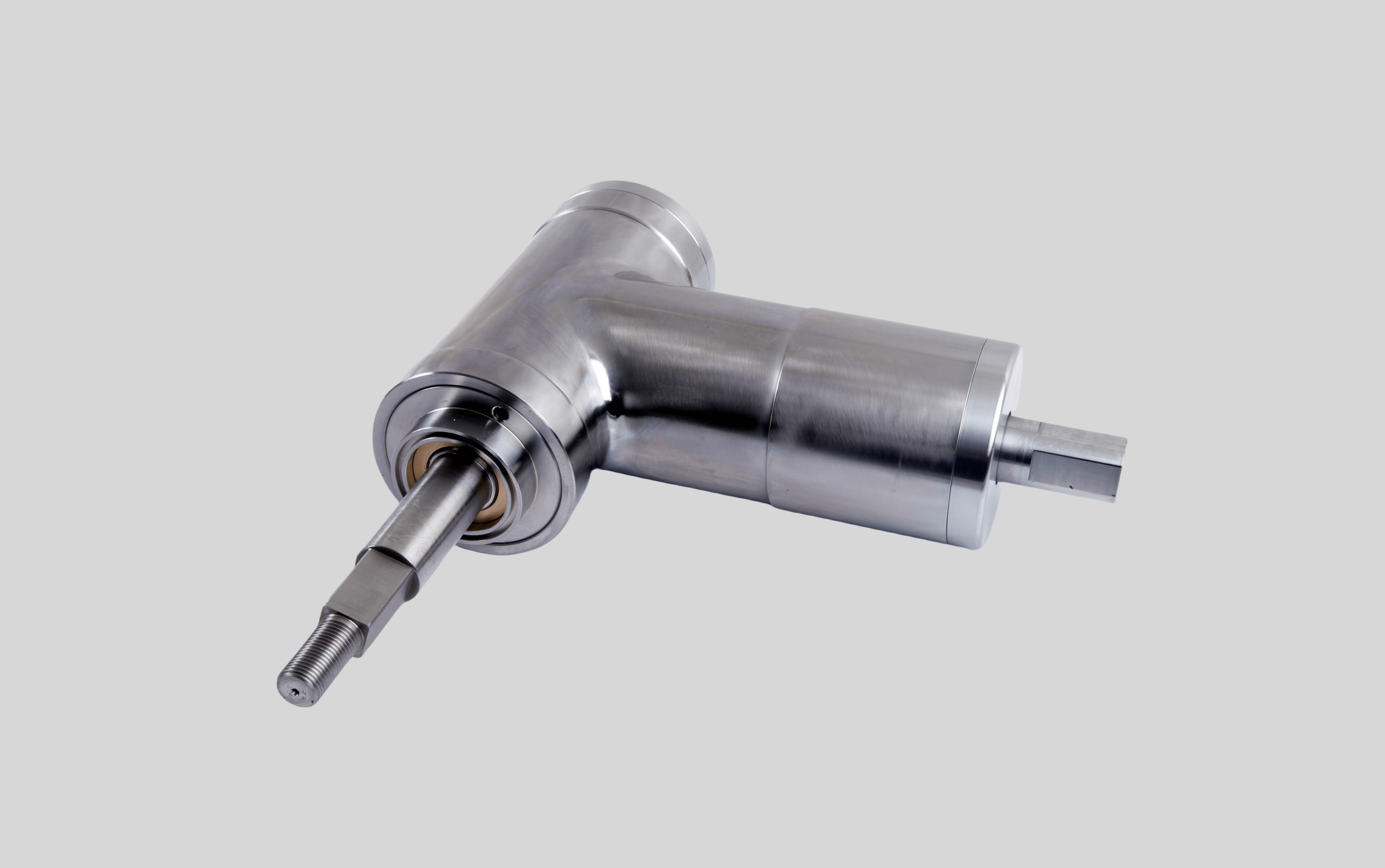

Working principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the lump-like materials under the rolling pressure of the rotor, passing through the screen holes. The finished granules are instantly discharged, with low heat generation, high efficiency, and good quality.

Electric lifting cone mill( ZLJ-270-Y)

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

In a barrel with an "8"-shaped cross-section, the material is pushed and sheared by two meshing screws, and is uniformly and stably transported to the crushing chamber for crushing.

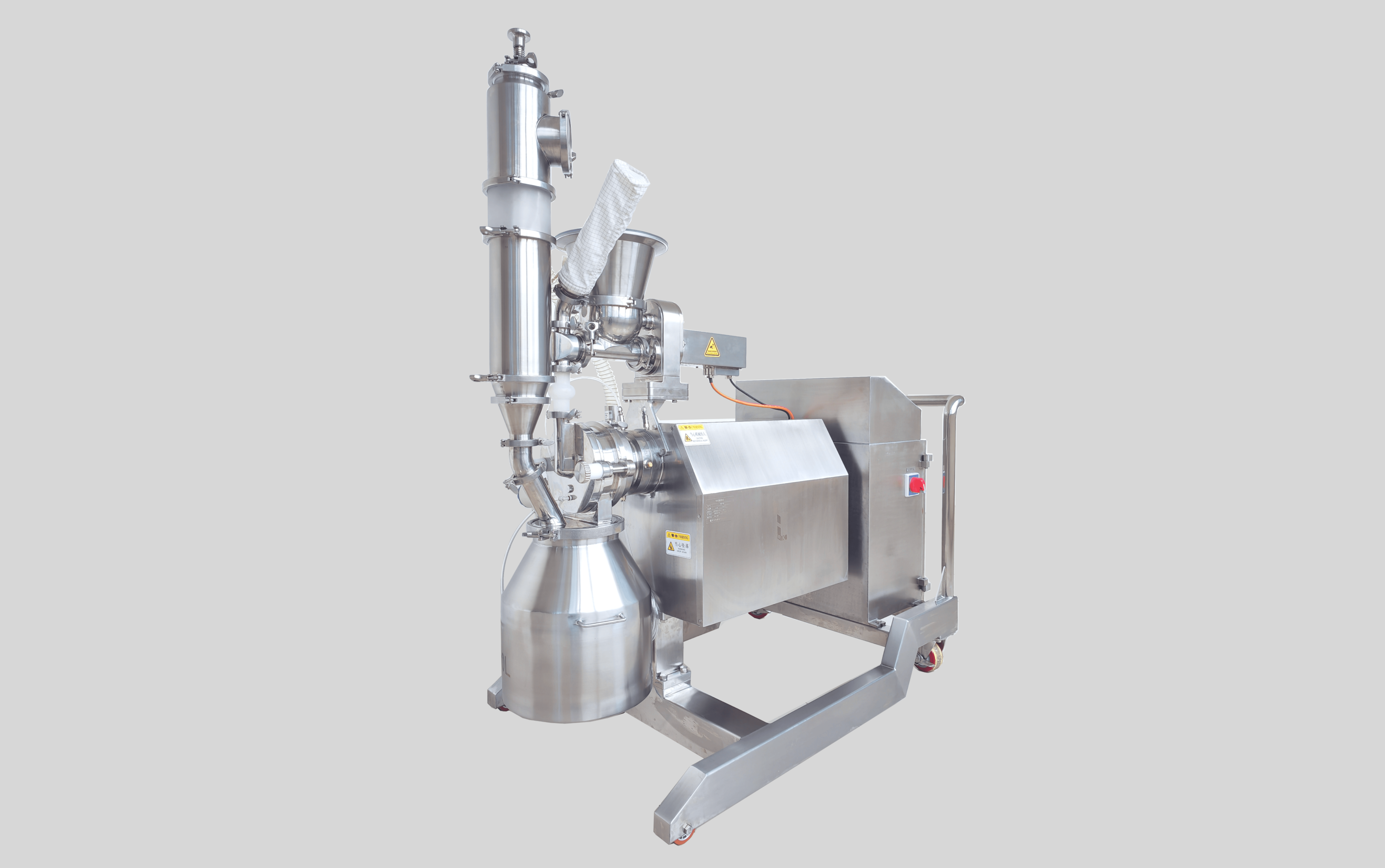

Multifunctional Crushing/Milling/Sifting machine (S-LAB)

Switching Between Crushing, Milling, and Sieving functions by component replacement.

Equipment Description: Under the action of the twin-screw, the material enters the pulverization chamber at a uniform speed. The feed port is located in the center of the pulverization chamber. Inside the pulverization chamber, there is a high-speed rotating needle disk rotor and a stationary needle disk stator. The annular needle bars of the two needle disks are alternately interlocked. The high-speed rotation of the rotor needle disk generates centrifugal force. The material enters from the center of the stator needle disk and, under the action of centrifugal force, passes through the needle bar forests of the two needle disks at high speed. The material and material and the material and the needle bar produce a large number of impacts, thereby achieving the effect of pulverization. In this process, the linear velocity of the material can reach 200m/s, and the minimum pulverization particle size can reach 9μm (D90).

Contact Information

Telephone

/ TEL

Address

/ ADD

No. 2, No. 712 Xiangfu Avenue, Shuangfu Street, jiangjin district, Chongqing

Scan mobile websites