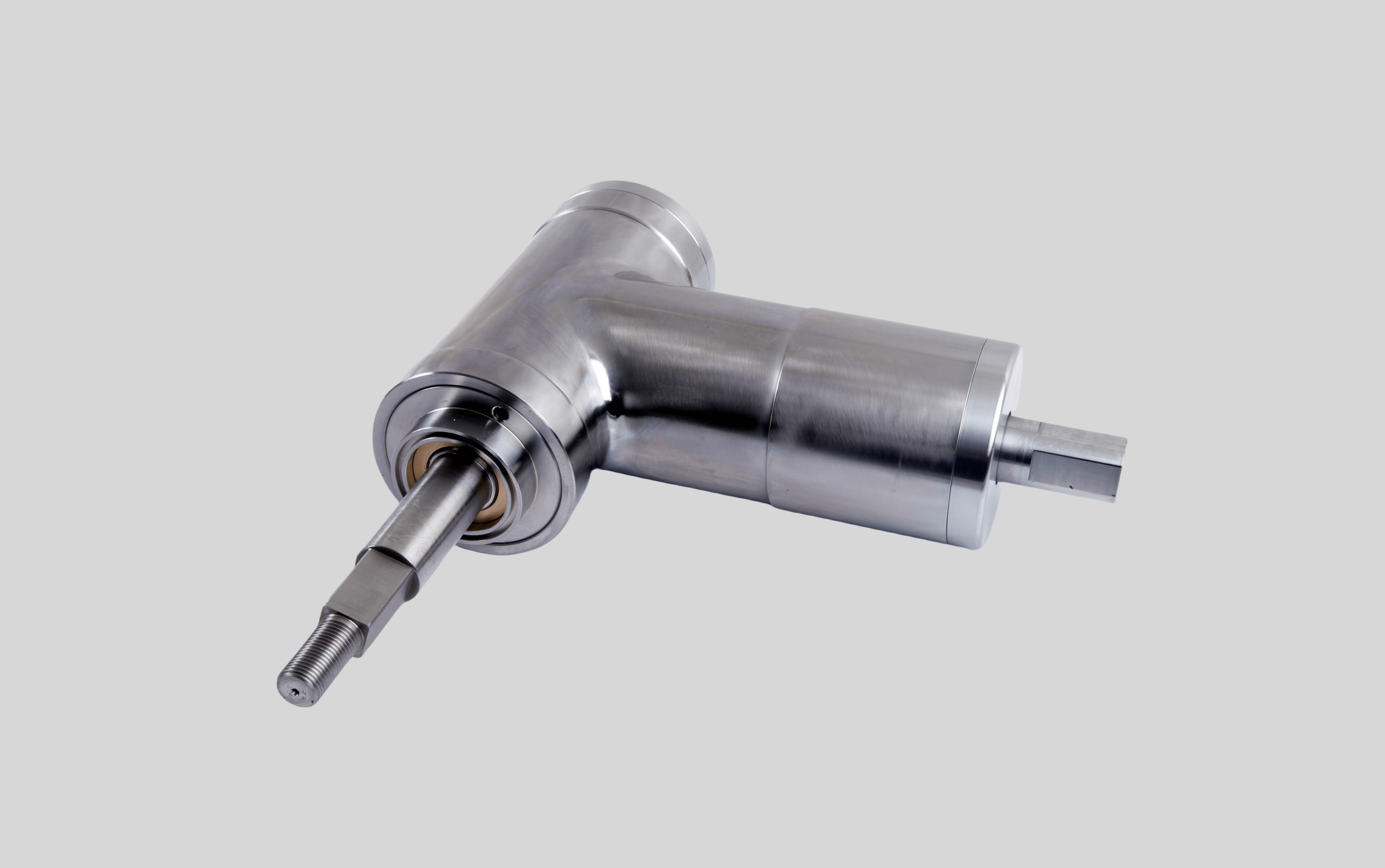

Whole grain machine head

Working principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the lump-like materials under the rolling pressure of the rotor, passing through the screen holes. The finished granules are instantly discharged, with low heat generation, high efficiency, and good quality.

Classification:

Email:

Whole grain machine head

Applications:Mainly for wet granulation and spray granulation and other agglomerated materials and unqualified tablets, it can be granulated according to the size requirements of the particles. It can also be used for the crushing and recycling of food and biscuits, as well as the crushing and granulation of other coarse raw materials. It is an ideal equipment for handling low-viscosity block, gum-like, and wet materials.

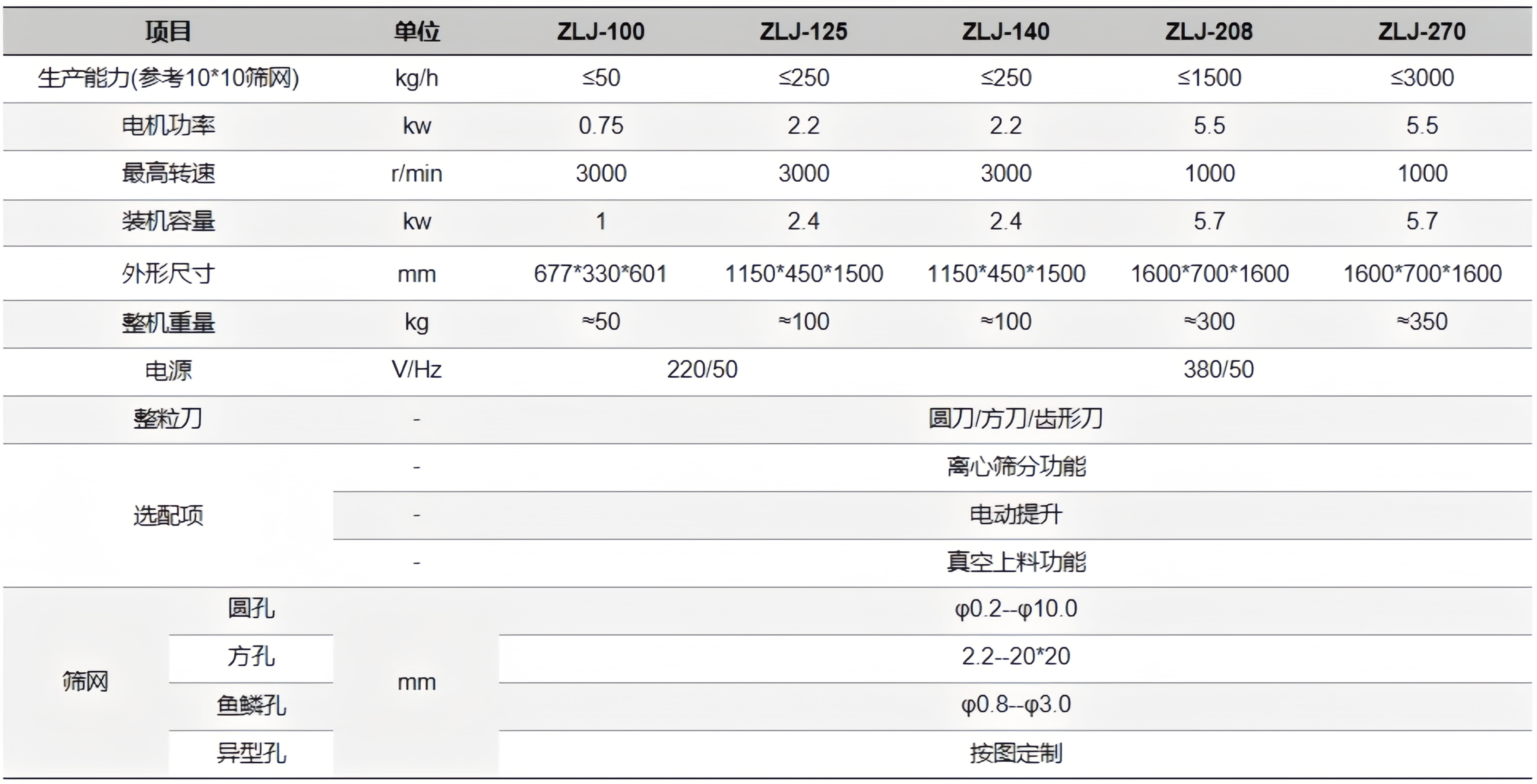

Technical Parameters:

Prev

Electric lifting cone mill( ZLJ-270-Y)

More products

Pulverization of active pharmaceutical ingredients(APIs),including hard,crystalline,and fibrous materials,as well as materials requiring very fine particle size.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

Chongqing Liweikang's self-designed whole grain machine's right-angle transmission system and shaft sealing technology greatly reduces the risk of material contamination.

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 023-65663700

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Contact Information

Telephone

/ TEL

Address

/ ADD

No. 2, No. 712 Xiangfu Avenue, Shuangfu Street, jiangjin district, Chongqing

Scan mobile websites