Product Series

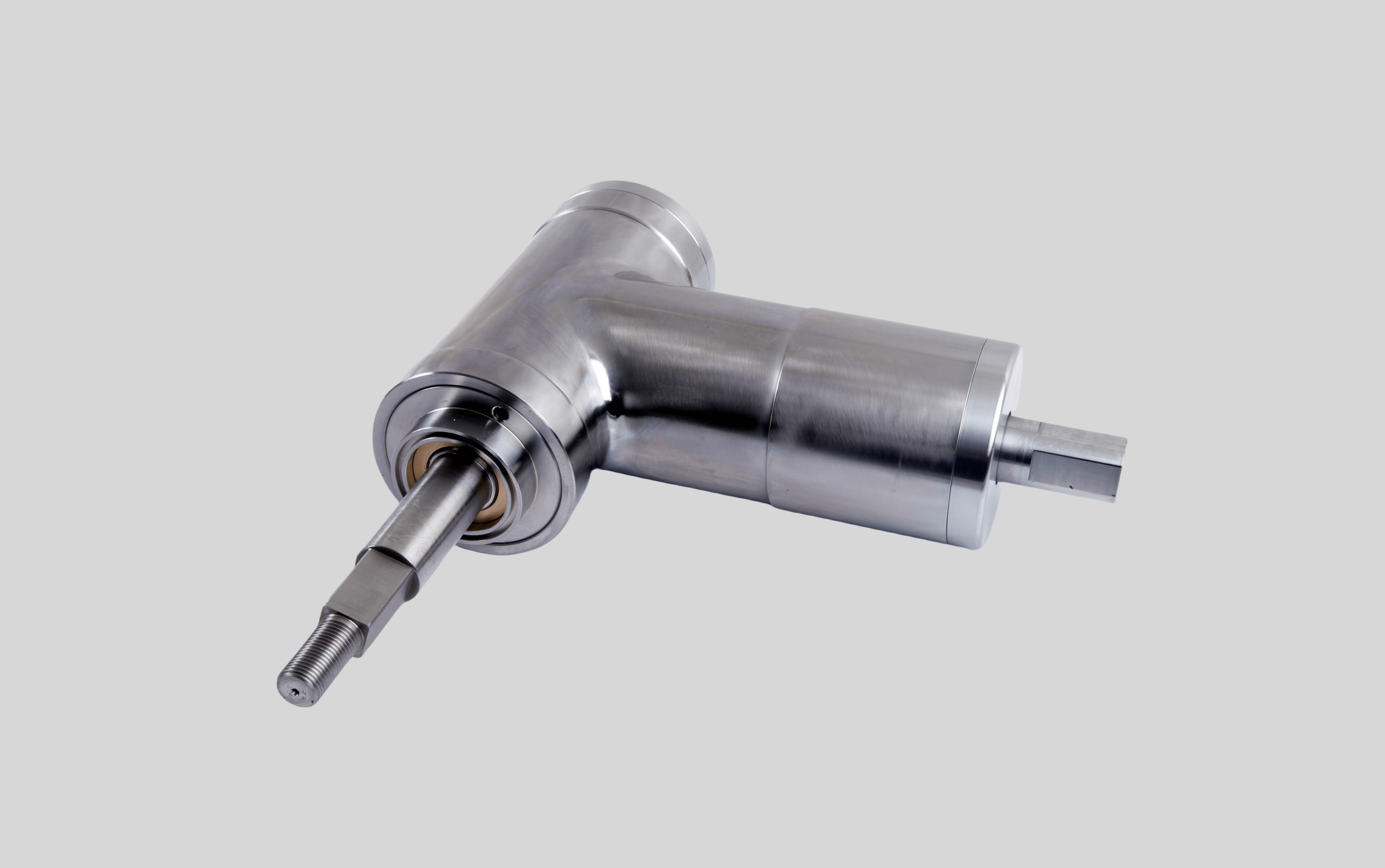

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

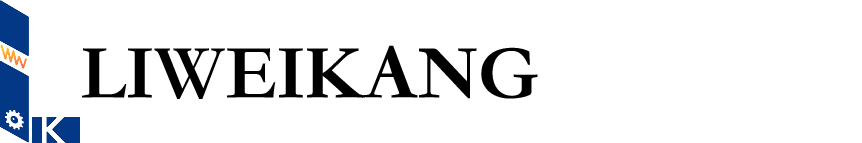

Chongqing Liweikang's self-designed whole grain machine's right-angle transmission system and shaft sealing technology greatly reduces the risk of material contamination.

Electric lifting cone mill(ZLJ-208-Y)

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

Three types of whole-grain knives: round whole-grain knife, square whole-grain knife, and toothed whole-grain knife, suitable for various materials with different properties.

Working principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the lump-like materials under the rolling pressure of the rotor, passing through the screen holes. The finished granules are instantly discharged, with low heat generation, high efficiency, and good quality.

Electric lifting cone mill( ZLJ-270-Y)

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

Multifunctional Crushing/Milling/Sifting machine (S-LAB)

Switching Between Crushing, Milling, and Sieving functions by component replacement.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

Working Principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly break down clump-like materials. Under the rolling pressure of the rotor, these materials pass through the screen holes to form granules. Finished granules are discharged instantly, resulting in less heat generation, high efficiency, and good quality.

Applications: Primarily used for wet granulation and spray granulation of clump-like materials and unqualified tablets. It can process materials to meet various particle size requirements. It can also be used for the recycling of food and biscuit crumbs and for the crushing and granulation of other coarse materials. It is an ideal device for processing low-viscosity, block-like, gum-like, and moist materials.

Technical Features:

● Modular design, enabling dry and wet granulation by changing granulation knives and screens.

● Screen openings as small as φ0.4mm, high opening rate, no dead corners; fine granulation particle size, high material throughput, effectively reducing the occurrence of material heating, easy to clean.

● High screen aperture accuracy, precisely controllable gap between the granulation knife and the screen, precise control of the particle size distribution of the material after granulation.

● Self-designed right-angle transmission system and shaft sealing technology, reducing the risk of material contamination.

● The entire working cavity is smoothly transitioned without dead corners, ensuring smooth material flow, less residue, and high yield.

● The entire machine uses quick-release clamps for simple and fast disassembly and installation, easy for operators to master.

Contact Information

Telephone

/ TEL

Address

/ ADD

No. 2, No. 712 Xiangfu Avenue, Shuangfu Street, jiangjin district, Chongqing

Scan mobile websites