Electric lifting cone mill( ZLJ-270-Y)

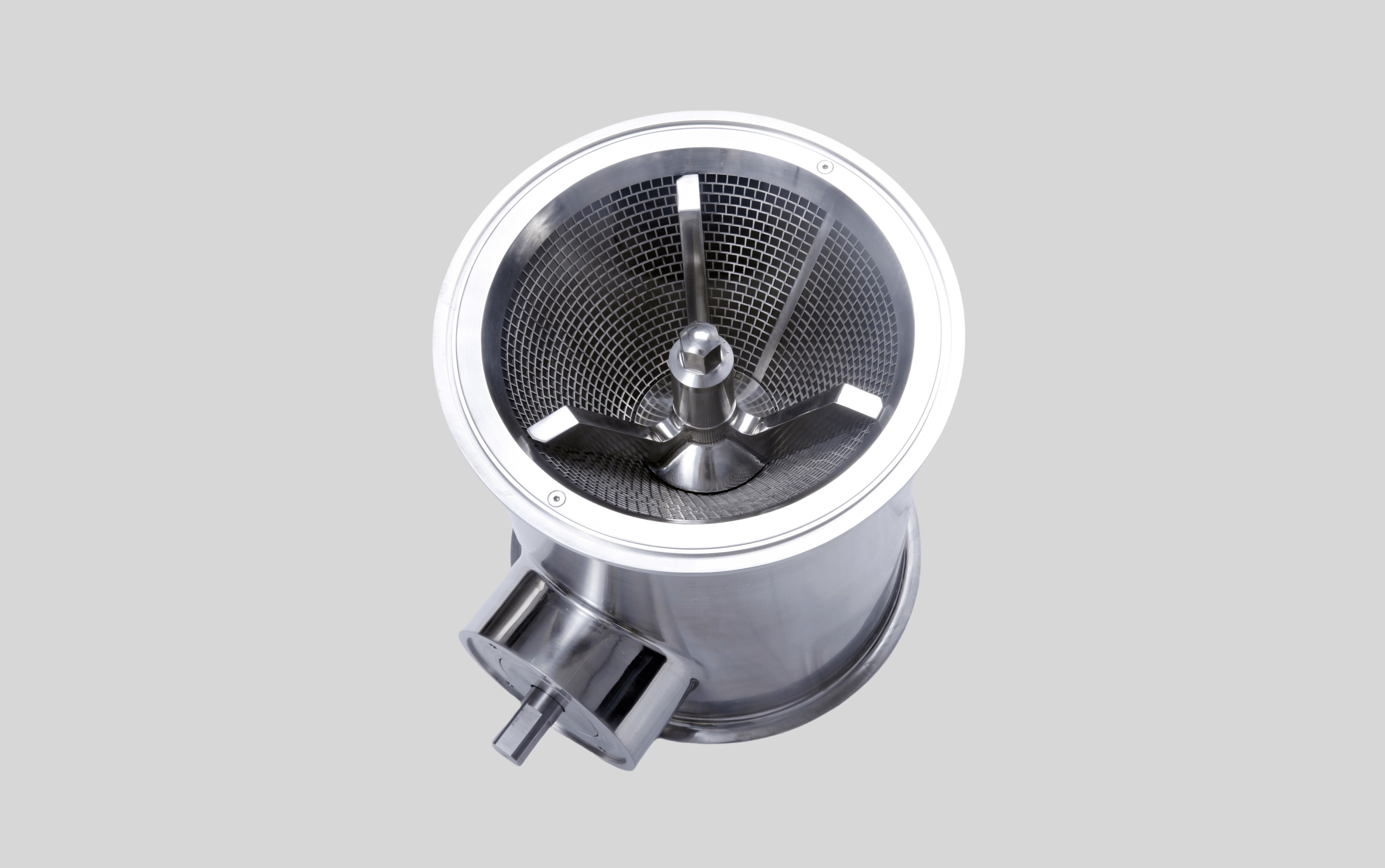

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

Classification:

Email:

Electric lifting cone mill( ZLJ-270-Y)

- Low heat generation

- High efficiency

- Modular Design

- Small screen aperture with high precision

- Easy to assemble and disassemble

- Four types of granulating screens (round,square,fish scale,and special-shaped holes)

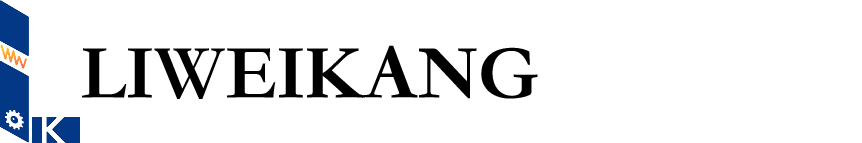

- Independently designed right-angle transmission system and shaft sealing technology

Application

Granulation can be performed according to the desired particle size, making it an ideal equipment for processing low-viscosity agglomerates,gum-like materials,and wet substances.

main components

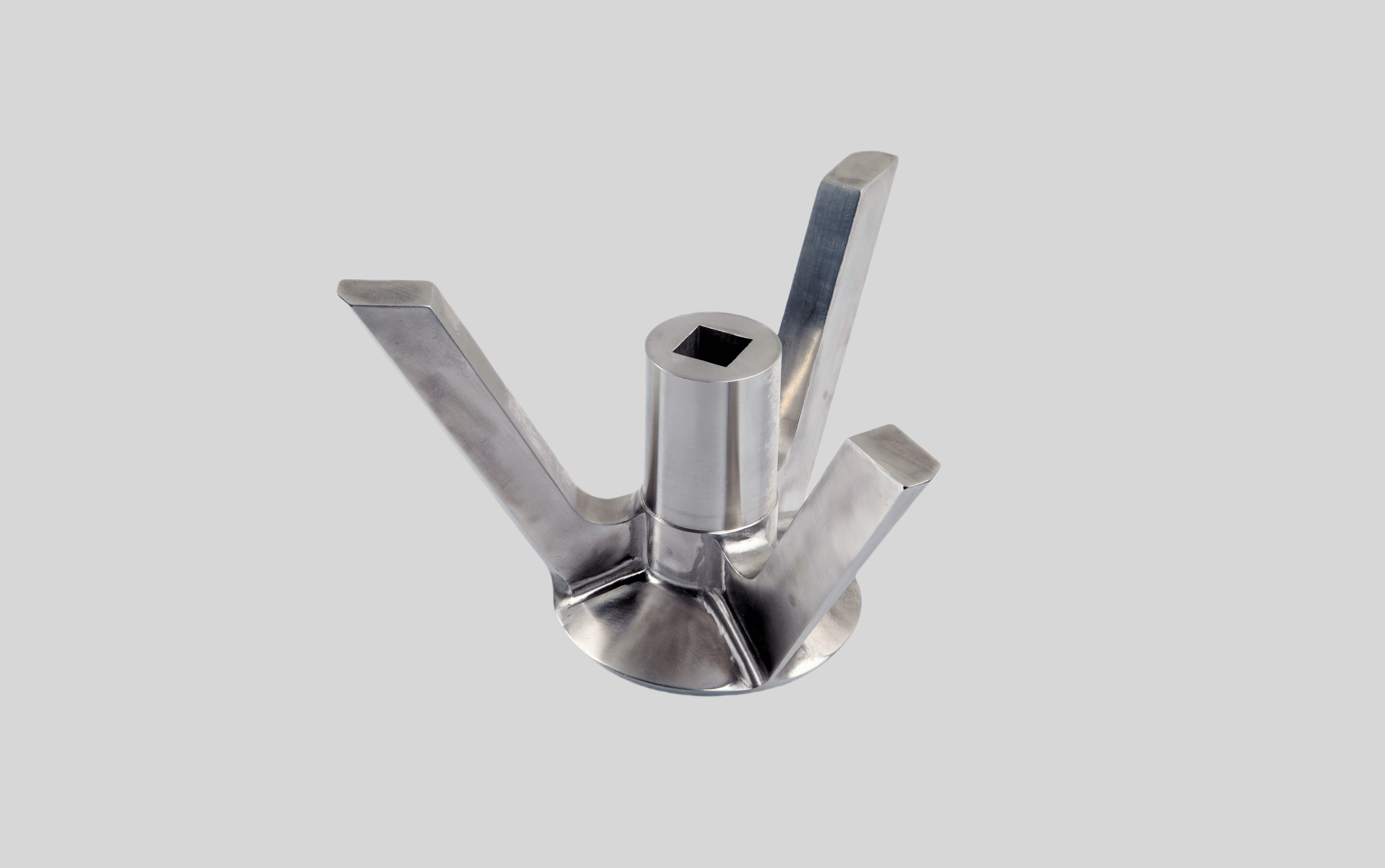

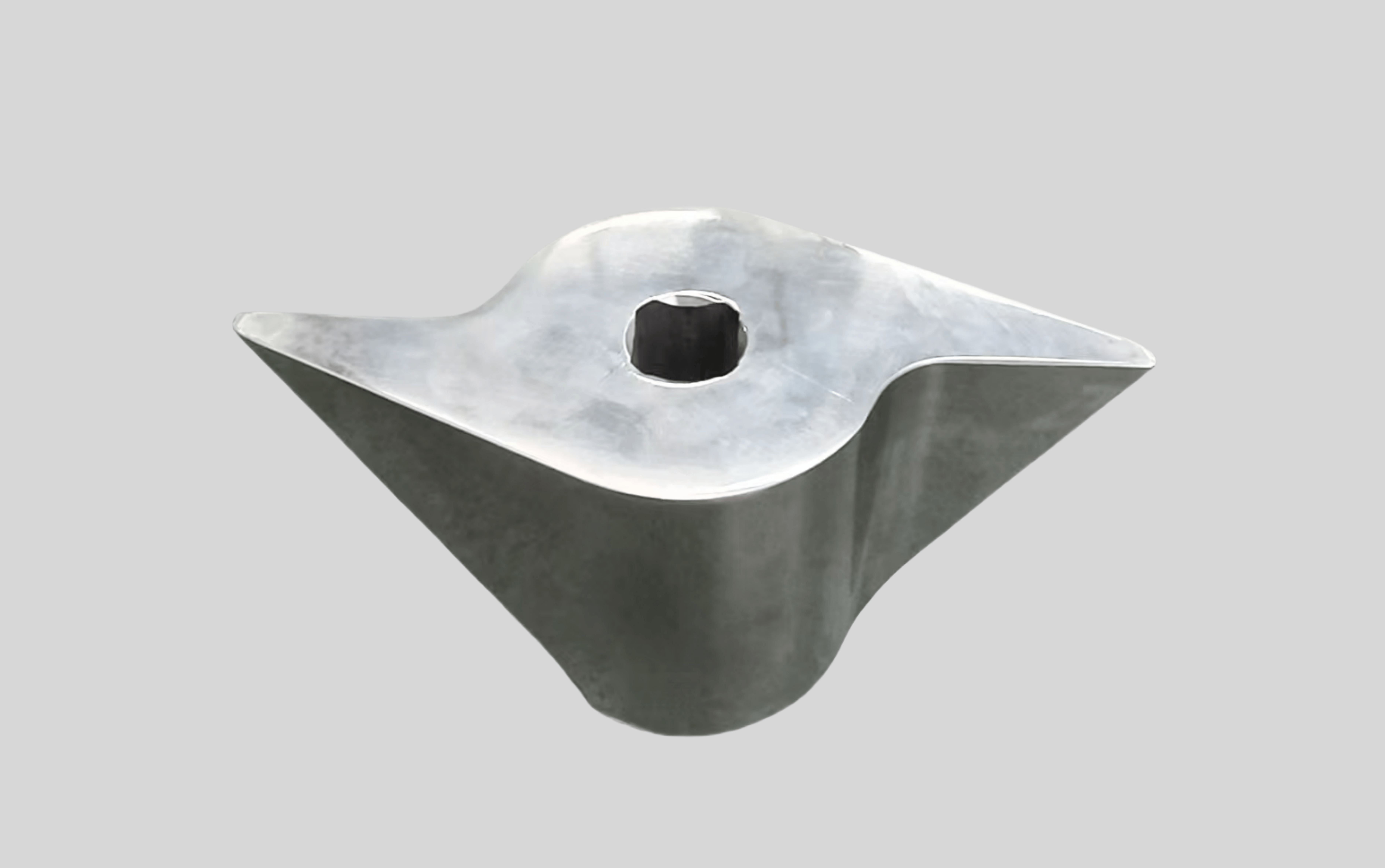

blade

square blade

round blade

tooth blade

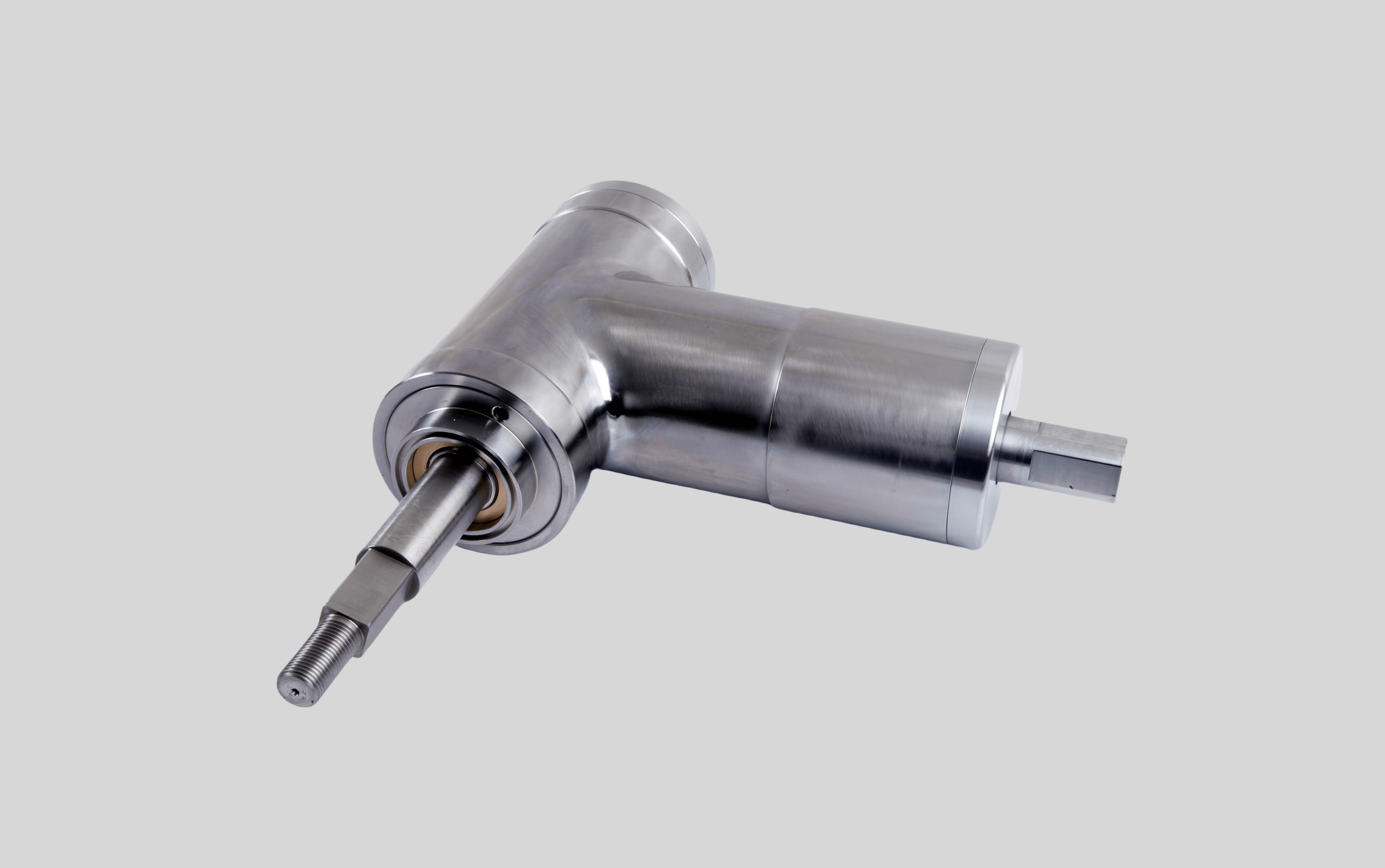

bagua blade

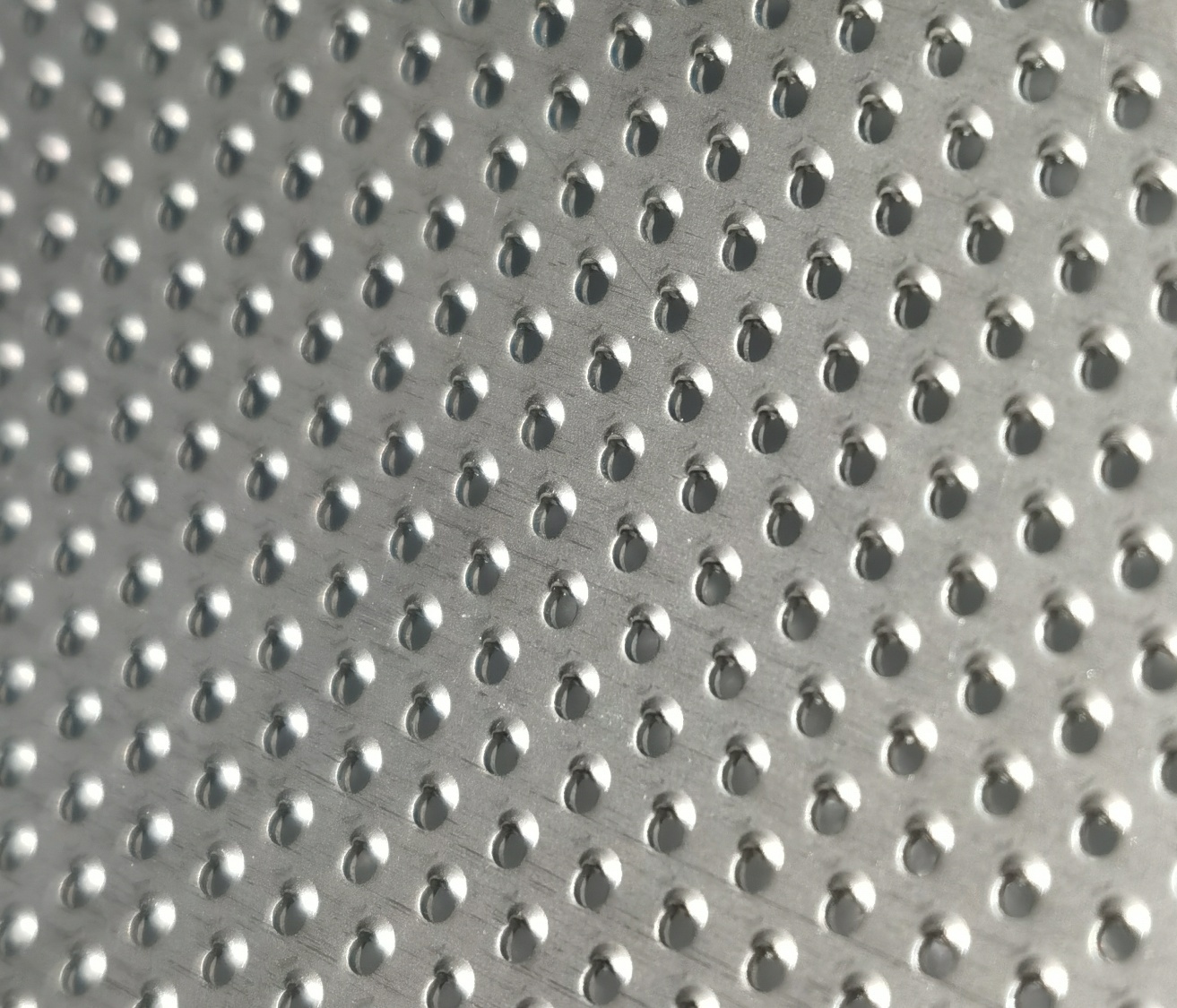

square hole

round hole

Friction hole

Double-layer

Transmission system

cleaning ball

Dispersing blade

head

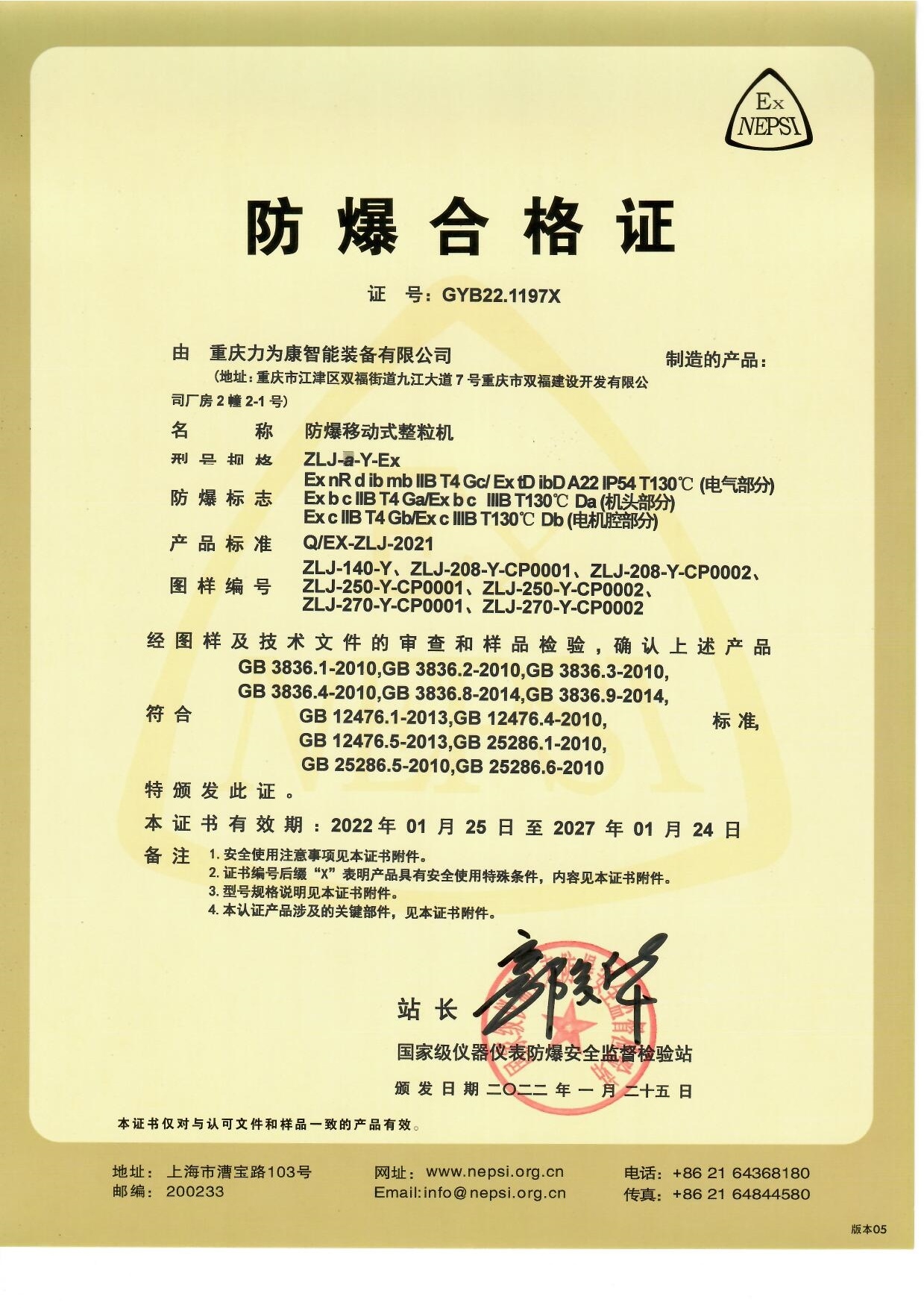

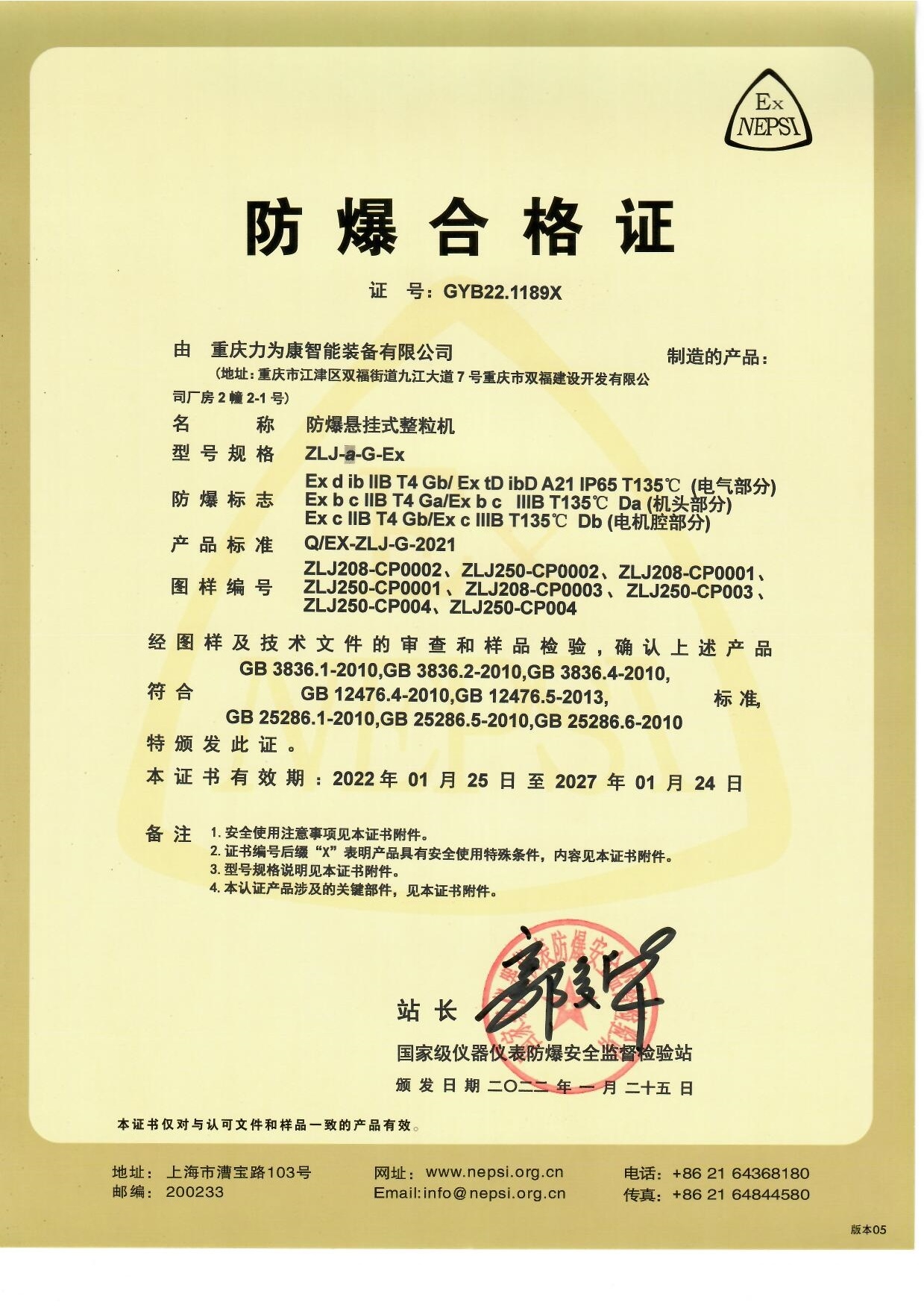

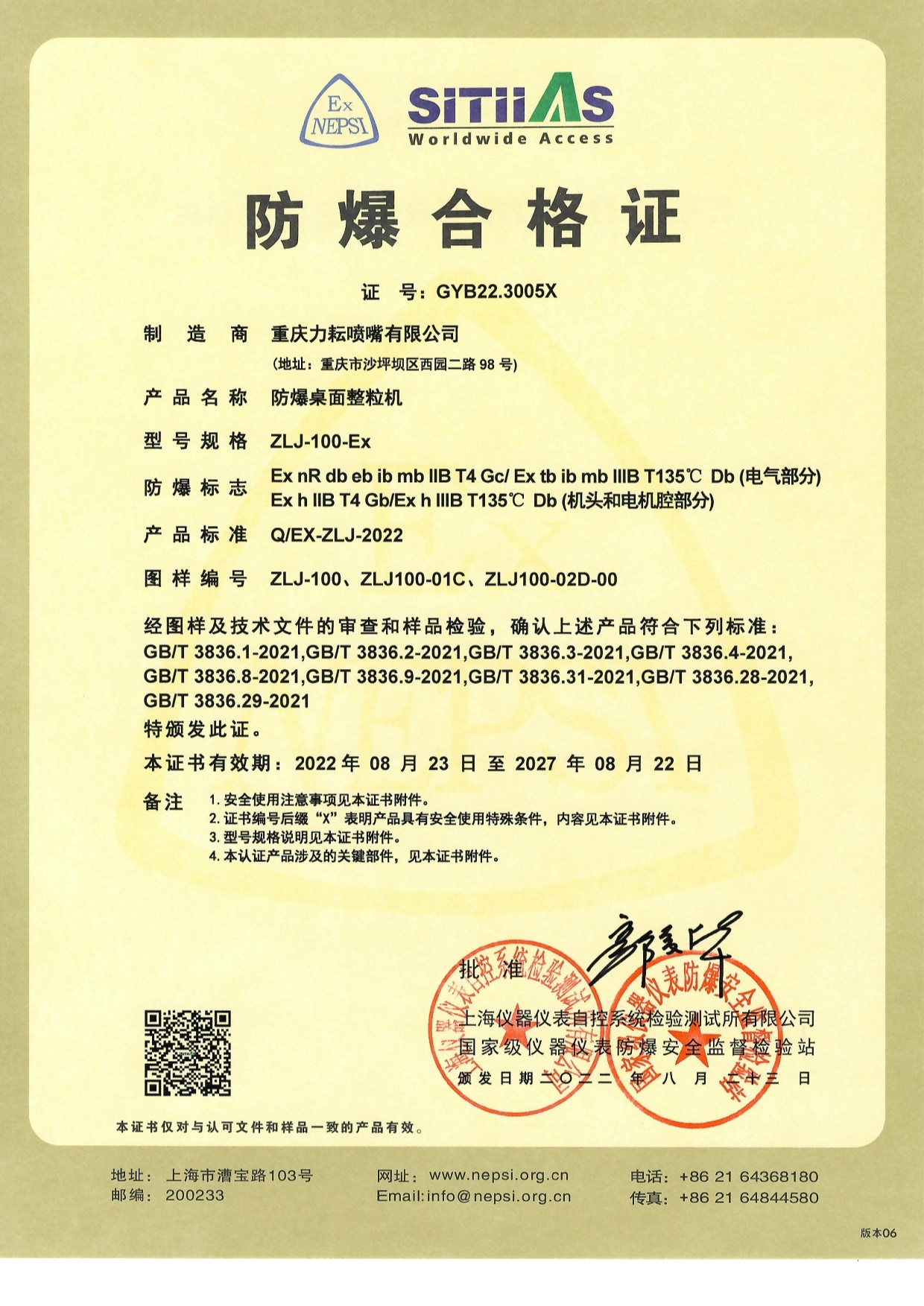

certificate

The first and only one in China to obtain the explosion-proof certificate for the entire machine(Explosion proof optional).

CE

explosion-proof

explosion-proof

explosion-proof

| Item | Unit | model | ||||||

| ZLJ-100 | ZLJ-125-Y | ZLJ-150-Y | ZLJ-208-Y | ZLJ-250-Y | ZLJ-270-Y | ZLJ-300-Y | ||

| Capacity | kg/h | ≤50 | ≤250 | ≤500 | ≤1500 | ≤2500 | ≤3000 | ≤6000 |

| Power of motor | kw | 0.75 | 2 | 3 | 5.5 | 5.5 | 5.5 | 5.5 |

| particle size | μm | 150~10000 | ||||||

| Maximum speed | r/min | 3000 | 2000 | 1450 | 1000 | 960 | 960 | 960 |

| Installed capacity | kw | 1 | 2.2 | 3.2 | 5.7 | 5.7 | 5.7 | 5.7 |

| Dimension | mm | 700*350*700 | 1050*450*1500 | 1050*450*1500 | 1500*700*1750 | 1550*700*1800 | 1550*700*1950 | 1850*750*1950 |

| power | V/Hz | 220/50 | 380/50 | |||||

| blade | N/A | round / square / tooth / bagua | ||||||

| Optional item | N/A | The equipment is explosion-proof | ||||||

| Centrifugation screening function | ||||||||

| Electric lift | ||||||||

| Vacuum feed function | ||||||||

| Screen mesh (Round) | mm | Φ0.4--Φ10.0 | ||||||

| Screen mesh (Square) | 2*2--20*20 | |||||||

| Screen mesh (friction) | Φ0.8--Φ3.0 | |||||||

| Screen mesh (Customized) | customize according to the diagram | |||||||

Prev

Multifunctional Crushing/Milling/Sifting machine (S-LAB)

More products

Pulverization of active pharmaceutical ingredients(APIs),including hard,crystalline,and fibrous materials,as well as materials requiring very fine particle size.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

Chongqing Liweikang's self-designed whole grain machine's right-angle transmission system and shaft sealing technology greatly reduces the risk of material contamination.

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 023-65663700

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Contact Information

Telephone

/ TEL

Address

/ ADD

No. 2, No. 712 Xiangfu Avenue, Shuangfu Street, jiangjin district, Chongqing

Scan mobile websites