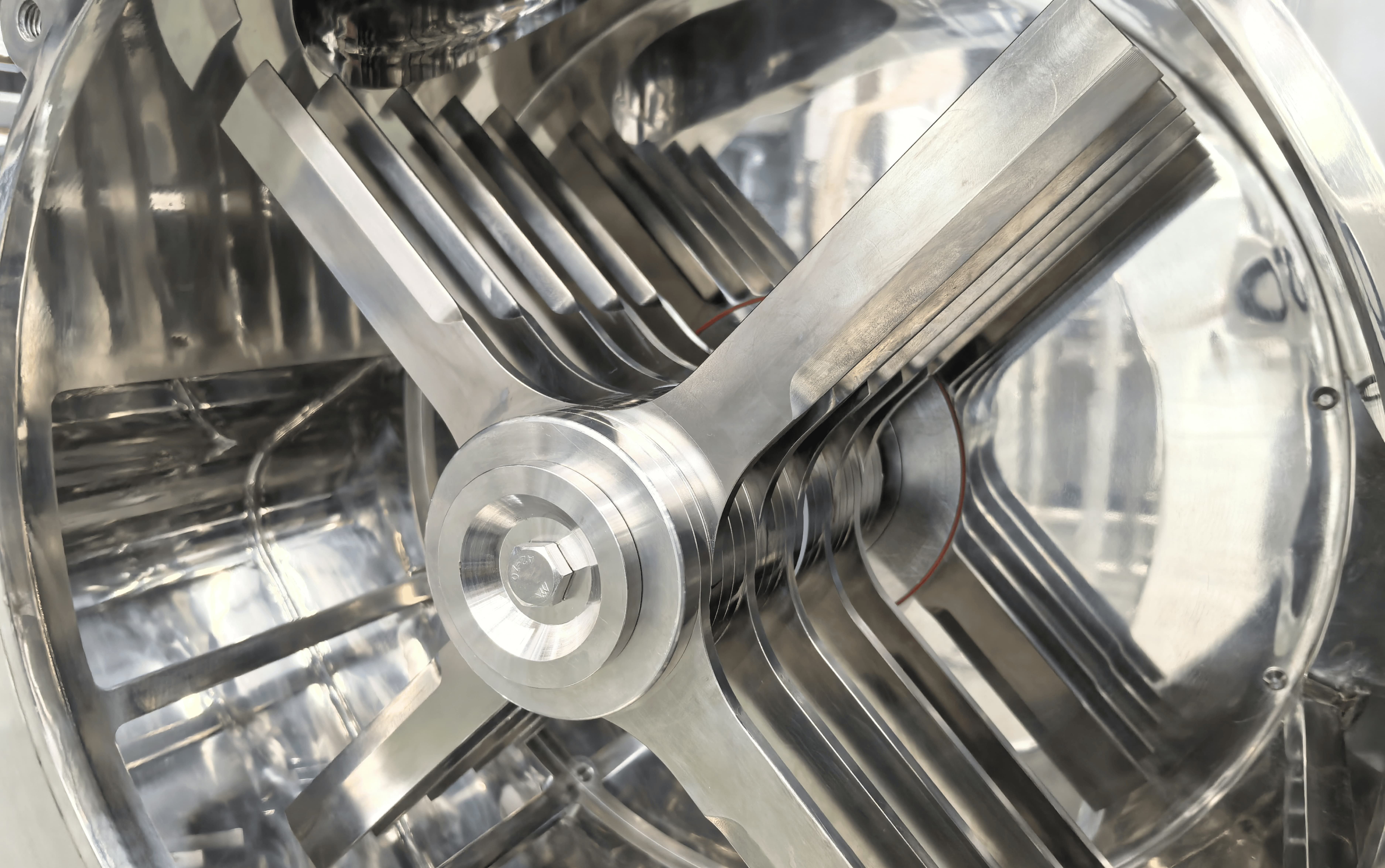

Hammer mill

Pulverization of active pharmaceutical ingredients(APIs),including hard,crystalline,and fibrous materials,as well as materials requiring very fine particle size.

Classification:

Email:

export@cqlypz.com

Hammer mill

- High rotation speed and high efficiency

- Integrated Modular Design

- Titanium Alloy(TC4) Crushing Blades

Capable of pulverizing a wide range of materials with different properties

- No dust Leakage

- Jacketed Water Cooling

- Customized Design

- Optional waterproof、dustproof、explosion-proof features

Application

The rotor with cutting edges rotates at high speed,creating high-speed relative motion with the precision small-aperture screen,and the material is pulverized by the rotor's hammer and cutting edges.

main components

working chamber

Double screw powder feeding

screen mesh

Double screw system

Main factors affecting the crushing effect

- Grinding blade speed (maximum linear speed)

- Design of Grinding blade (blade thickness)

- powder feed rate

- Inlet position

- Material properties

- mesh aperture

Partial experimental data sharing of hammer mill

| Material Name | feature | Before the experiment | Before the experiment |

| penicillin | Freeze dried block shaped particles | Massive | 57.4μm |

| Orange essence | Has a certain degree of stickiness | 106μm | 29.1μm |

| Amoxicillin | Dry pressed granules | Particle powder | All passed through 65mesh |

| Fumaric acid | Need to control the temperature below 60 ℃ | powder | 35.1μm |

| blueberry | Blueberry fruit | Blueberry fruit | 130μm |

| citric acid | Easy to decompose due to moisture | small particles | 35.8μm |

| Sucralose | / | 78μm | 6.5μm |

| Probiotics | Block | Block | 37μm |

| Ibuprofen | Melting point: 70℃ | >100μm | 55.8μm |

Item | Unit | model | ||||

FSJ-140mini | FSJ-140 | FSJ-210 | FSJ-280 | FSJ-420 | ||

Capacity | kg/h | ≤10 | ≤60 | ≤300 | ≤1200 | ≤2500 |

Power of motor | kw | 0.75 | 2.2 | 5.5 | 7.5 | 11 |

particle size | μm | 25-200 | ||||

Maximum speed | r/min | 15000 | 15000 | 10000 | 7500 | 6000 |

Installed capacity | kw | 1 | 2.5 | 7 | 9 | 13 |

| Dimension | mm | 800*350*700 | 900*700*1300 | 1000*850*1650 | 1600*900*1900 | 2000*1000*1950 |

| power | V/Hz | 220/50 | 380/50 | |||

Double screw feeder | N/A | Double screw feeder | Double screw feeder | Double screw feeder | Electric multi-page butterfly valve | Electric multi-page butterfly valve |

cooling system | N/A | N/A | Surrounding water-cooled crushing chamber+Axial system with water cooling and air cooling. | |||

Prev

Prev

Hammer mill laboratorial(FSJ-140mini)

More products

Pulverization of active pharmaceutical ingredients(APIs),including hard,crystalline,and fibrous materials,as well as materials requiring very fine particle size.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

Hot melt spray congealing is a process in which molten material (hot melt) is broken into fine droplets by an atomizer (spray), rapidly cooled and solidified in a condensing medium (congealing), and finally transformed into solid particles with specific shapes and properties.

Utilizes vacuum fluidized bed technology and spray drying technology to achieve thermal and mass transfer, enabling multifunctional granulation, coating, and pelletizing of materials.

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 023-65663700

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Contact Information

Telephone

Address

No. 712-2 Xiangfu Avenue, Shuangfu Street, Jiangjin District, Chongqing, China

Scan mobile websites