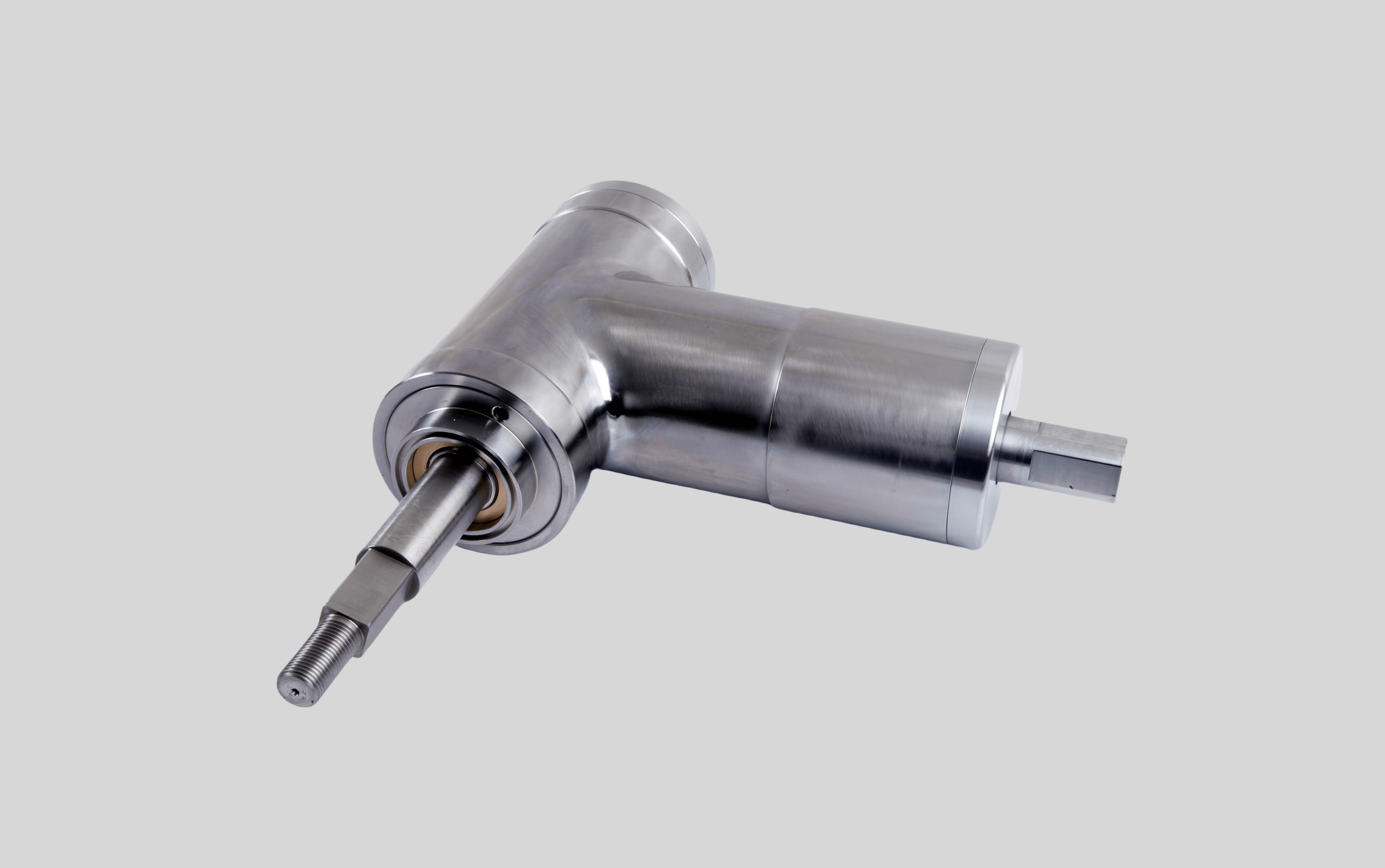

Needle pulverizer

Equipment Description: Under the action of the twin-screw, the material enters the pulverization chamber at a uniform speed. The feed port is located in the center of the pulverization chamber. Inside the pulverization chamber, there is a high-speed rotating needle disk rotor and a stationary needle disk stator. The annular needle bars of the two needle disks are alternately interlocked. The high-speed rotation of the rotor needle disk generates centrifugal force. The material enters from the center of the stator needle disk and, under the action of centrifugal force, passes through the needle bar forests of the two needle disks at high speed. The material and material and the material and the needle bar produce a large number of impacts, thereby achieving the effect of pulverization. In this process, the linear velocity of the material can reach 200m/s, and the minimum pulverization particle size can reach 9μm (D90).

Classification:

Email:

Needle pulverizer

Process Applications:Suitable for dry ultrafine grinding of various brittle, crystalline, heat-sensitive, and medium-to-low hardness materials. Applied in chemical, pharmaceutical, and food industries, with high efficiency and no dust leakage.

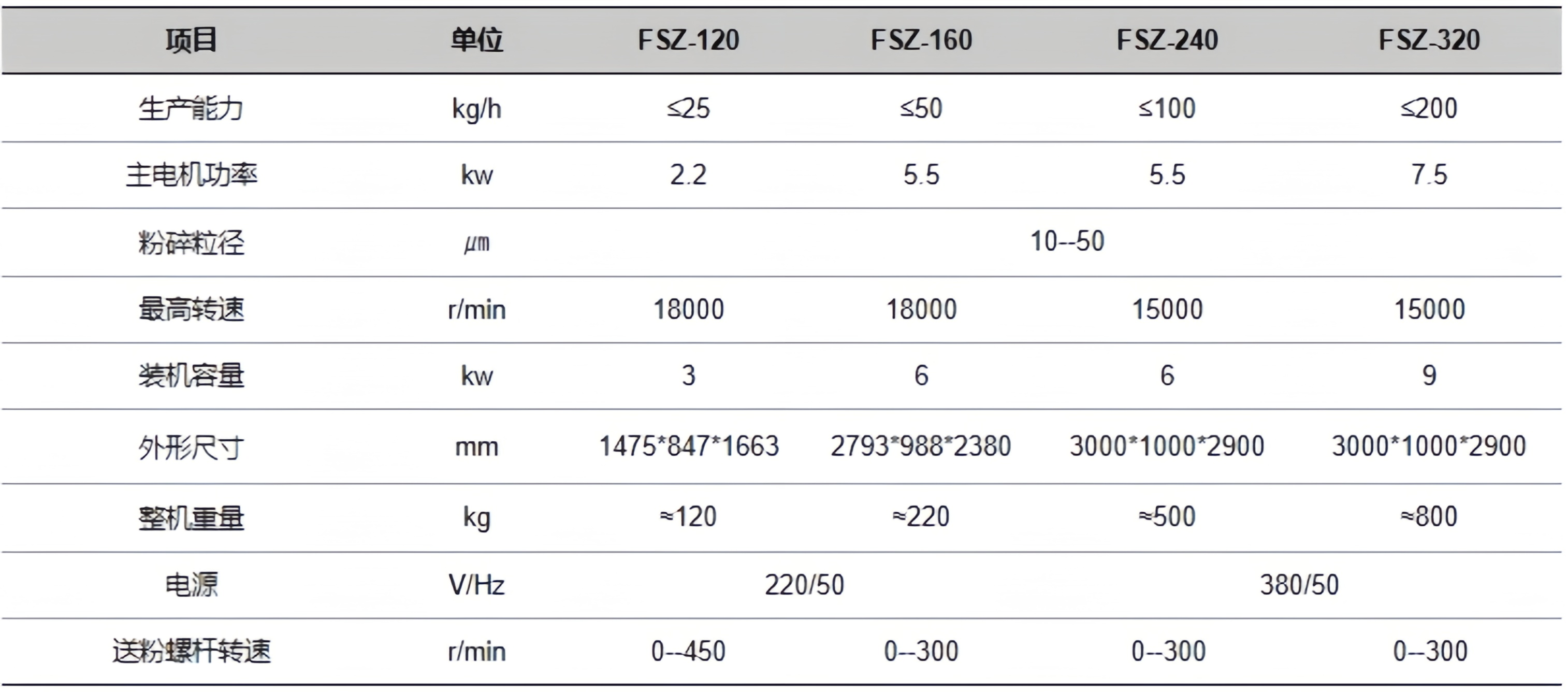

Technical Parameters:

*This company reserves the right to interpret the product description on this page. Technical parameters are subject to change due to product upgrades and updates.

Prev

Next

Prev

Needle pulverizer

Next

More products

Pulverization of active pharmaceutical ingredients(APIs),including hard,crystalline,and fibrous materials,as well as materials requiring very fine particle size.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

Chongqing Liweikang's self-designed whole grain machine's right-angle transmission system and shaft sealing technology greatly reduces the risk of material contamination.

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 023-65663700

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Contact Information

Telephone

/ TEL

Address

/ ADD

No. 2, No. 712 Xiangfu Avenue, Shuangfu Street, jiangjin district, Chongqing

Scan mobile websites