Product Series

Customizable mixing tanks of various models: single/double-layer, pneumatic, explosion-proof, electric heating

High-efficiency wet granulator

Working principle: Powdery materials are mixed in a sealed container through the rotation of the stirring paddle to form a semi-fluid state, allowing for complete mixing; meanwhile, a binder and an appropriate amount of water are injected, forming moist soft material, which is then chopped by the high-speed rotation of the horizontal cutting knife and made into uniform moist granules through the granulation mechanism. This equipment is widely used in the pharmaceutical, food, and chemical industries and is an ideal equipment for laboratory process exploration and practical teaching.

Rotary swaging and extrusion rounding machine

Product Overview: Utilizing twin-blade rotary extrusion, the feed blade and extrusion blade, combined with low-shear technology, reduce energy consumption and temperature rise, enabling adaptability to a wide range of materials and making it ideal for processing sensitive materials. Multiple screen models are available to optimize particle size, surface quality, and particle size distribution. Suitable for batch and continuous production. Modular design facilitates cleaning.

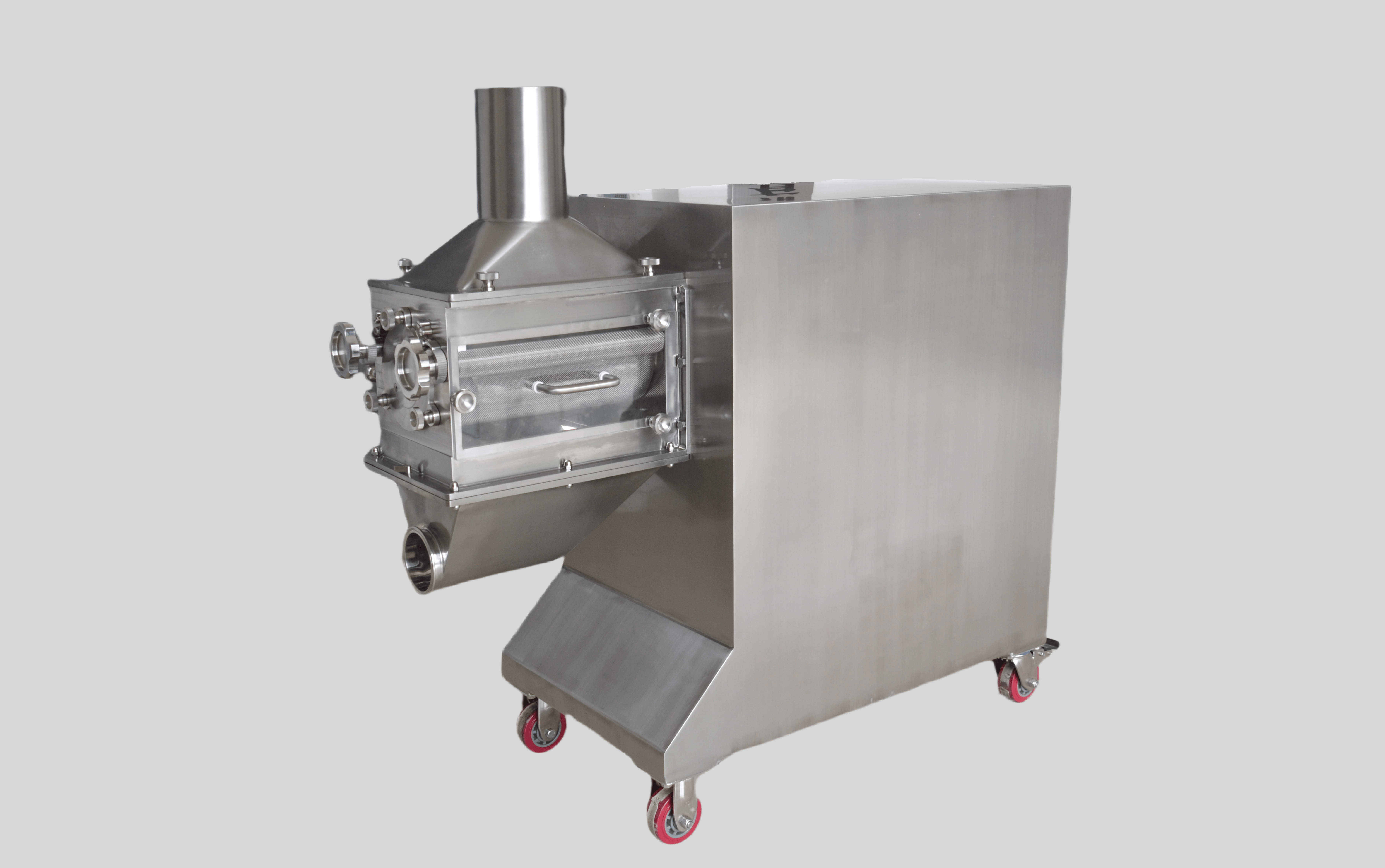

The YB-160 oscillating granulator is a specialized device that uses the forward and reverse rotation of a rotating drum to force a wet powder mixture through a screen to produce granules. It is an innovative and optimized granulator designed by our company to meet the needs of our customers and to seamlessly connect with highly efficient wet granulation processes.

The multifunctional fluidized bed is a multifunctional granulation and drying equipment that uses negative pressure boiling fluidization technology and spray drying technology to achieve heat and mass transfer for material granulation, coating, and pelletizing. The system adopts PLC program control technology and air intake proportion control technology, making the granulation, coating, and pelletizing drying process stable, highly efficient, and highly automated. It is suitable for granulating, coating, and pelletizing powders and granular materials, and is widely used in the material granulation and drying processes in the pharmaceutical, food, chemical, and feed industries.

Product Introduction: The extrusion rolling machine is mainly suitable for microsphere preparation technology. Its working principle is to use a rotating screw to convey and extrude wet raw materials to a spherical dome. The spherical dome extrudes the materials into strips, and then uses a high-speed rotating gear disc to roll the strip-shaped materials into dense spherical microspheres. Microspheres have been widely used in the field of pharmaceutics. As a drug carrier, it can be further pressed into tablets or filled into empty capsules. It not only improves drug stability but also effectively regulates the drug release rate; as a drug delivery system, microspheres have therapeutic advantages, such as less gastrointestinal irritation and reduced risk of drug burst release, improving drug safety and good blood drug concentration reproducibility; microspheres also have good fluidity, low friability, easy filling and other process advantages. In pharmaceutical production, compared with other methods of making pills, extrusion rolling technology is an advanced process method widely used in the international pharmaceutical industry. In controlled-release preparations and drug utilization, many factors in extrusion rolling can change the powder properties of microspheres and the release behavior of drugs; the measurement indicators of microsphere quality mainly include: microsphere particle size, roundness, friability, density, fluidity, drug dissolution and the microstructure of the microsphere surface, etc. Through independent and detailed examination of various factors, the properties of microspheres can be improved purposefully to achieve the expected drug purpose.

Multifunctional pellet making, granulating and coating machine

Equipment Description: The multifunctional granulator and coating machine adopts a modular design. Different functional modules can be added according to usage requirements, realizing the free switching of centrifugal granulation, extrusion rolling, and cutting spray granulation. Through the quick conversion of the rotating disc and the gear disc, the machine simultaneously has the functions of starting, granulating, coating, extruding, and rolling. It has two microsphere preparation methods: centrifugal granulation and tangential spray granulation. Finished microspheres can also be put into the material tank and sprayed with atomized coating liquid for coating. The microspheres have good sphericity, uniform size, and high drug utilization rate. They are suitable for sustained-release drug granulation, enteric-coated drug granulation, microsphere coating, and other processes. It is an ideal equipment for exploring microsphere preparation processes and formula development. The application of microspheres in the field of pharmaceutics is very extensive. As a drug carrier, it can be further pressed into tablets or put into empty capsules. This not only improves drug stability, but also effectively regulates the drug release rate; as a drug delivery system, microspheres have therapeutic advantages, such as less gastrointestinal irritation and reduced risk of drug bolus release, improving drug safety and good reproducibility of blood drug concentration; microspheres also have good fluidity, low friability, easy filling, and other processing advantages.

FF-100 Rotary Extrusion Machine

Product Overview: Utilizing twin-blade rotary extrusion, the feed blade and extrusion blade, combined with low-shear technology, reduce energy consumption and temperature rise, enabling broad material adaptability and making it ideal for processing sensitive materials. Multiple screen models are available to optimize particle size, surface quality, and size distribution. Suitable for both batch and continuous production.

FF-220 Rotary Extrusion Machine

Product Overview: Utilizing twin-blade rotary extrusion, the feed blade and extrusion blade, combined with low-shear technology, reduce energy consumption and temperature rise, enabling broad material adaptability and making it ideal for processing sensitive materials. Multiple screen models are available to optimize particle size, surface quality, and size distribution. Suitable for both batch and continuous production.

Contact Information

Telephone

/ TEL

Address

/ ADD

No. 2, No. 712 Xiangfu Avenue, Shuangfu Street, jiangjin district, Chongqing

Scan mobile websites