Product Series

Hot melt spray congealing is a process in which molten material (hot melt) is broken into fine droplets by an atomizer (spray), rapidly cooled and solidified in a condensing medium (congealing), and finally transformed into solid particles with specific shapes and properties.

Utilizes vacuum fluidized bed technology and spray drying technology to achieve thermal and mass transfer, enabling multifunctional granulation, coating, and pelletizing of materials.

Mixing, Moistening, and Granulating of Powder Materials, Widely Used in Pharmaceuticals, Food, and Chemical Industries

Utilizes vacuum fluidized bed technology and spray drying technology to achieve thermal and mass transfer, enabling multifunctional granulation, coating, and pelletizing of materials.

The prepared microgranules can be further compressed into tables or filled into empty capsules.

Materials are fed from the hopper and pass through a breaker knife into the extrusion chamber, where a feeding knife and an extrusion knife cooperate with low-shear technology to rotate and extrude the materials. The strands are then rounded into dense spherical microgranules by a high-speed rotating toothed disc.

Customizable mixing tanks of various models: single/double-layer, pneumatic, explosion-proof, electric heating

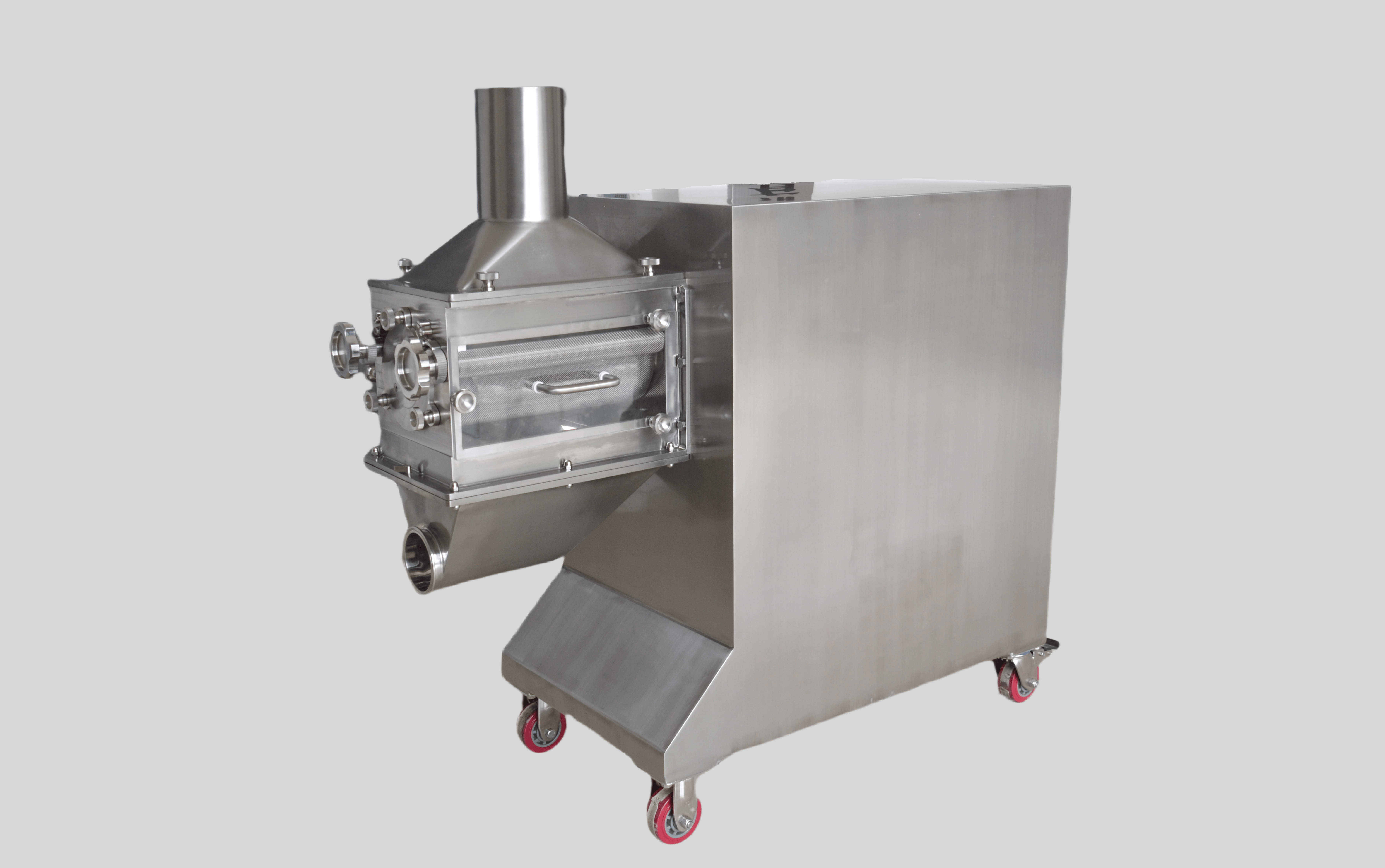

The YB-160 oscillating granulator is a specialized device that uses the forward and reverse rotation of a rotating drum to force a wet powder mixture through a screen to produce granules. It is an innovative and optimized granulator designed by our company to meet the needs of our customers and to seamlessly connect with highly efficient wet granulation processes.

Contact Information

Telephone

Address

No. 712-2 Xiangfu Avenue, Shuangfu Street, Jiangjin District, Chongqing, China

Scan mobile websites