Product Series

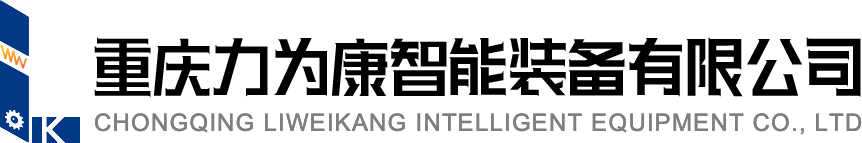

Desktop whole grain machine ZLJ-100

Working principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the block-like materials under the pressure of the rotor, passing through the screen holes, and the finished granules are instantly discharged. It features low heat generation, high efficiency, and good quality. Variable frequency speed regulation allows for adjustable main shaft speed with a wide range. The bottom drive ensures smooth feeding.

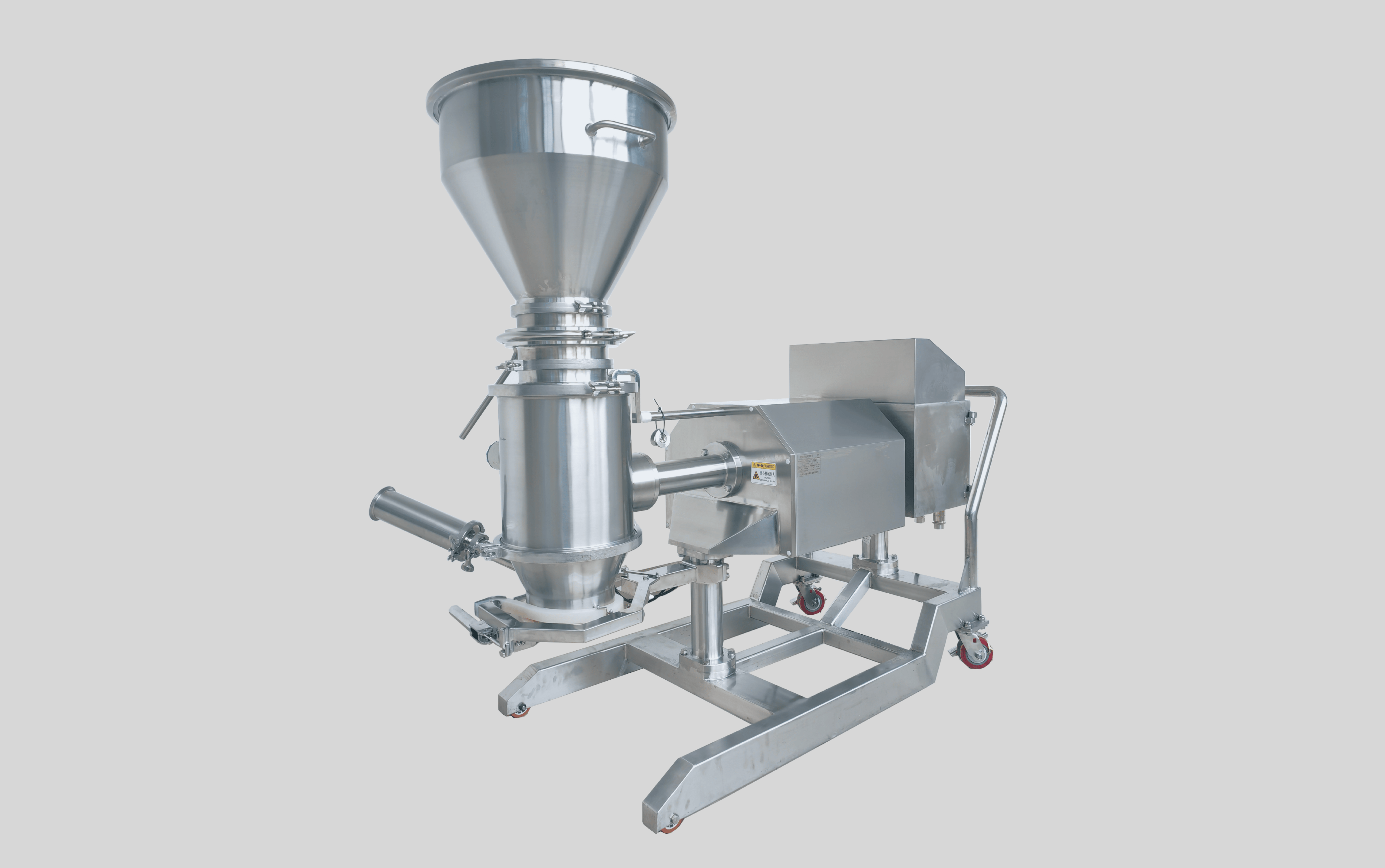

Mobile whole grain machine ZLJ-208-Y

Working principle: This machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the block-like materials under the pressure of the rotor, passing through the screen holes. The finished granules are discharged instantly, resulting in less heat generation, high efficiency, and good quality. It adopts frequency conversion speed regulation, the main shaft speed is adjustable, and the range is wide. The lower drive ensures smooth feeding. The parts of the machine that contact the materials and the external parts are made of high-quality stainless steel with a polished surface. It can be used with wet granulation machines and fluidized bed drying equipment.

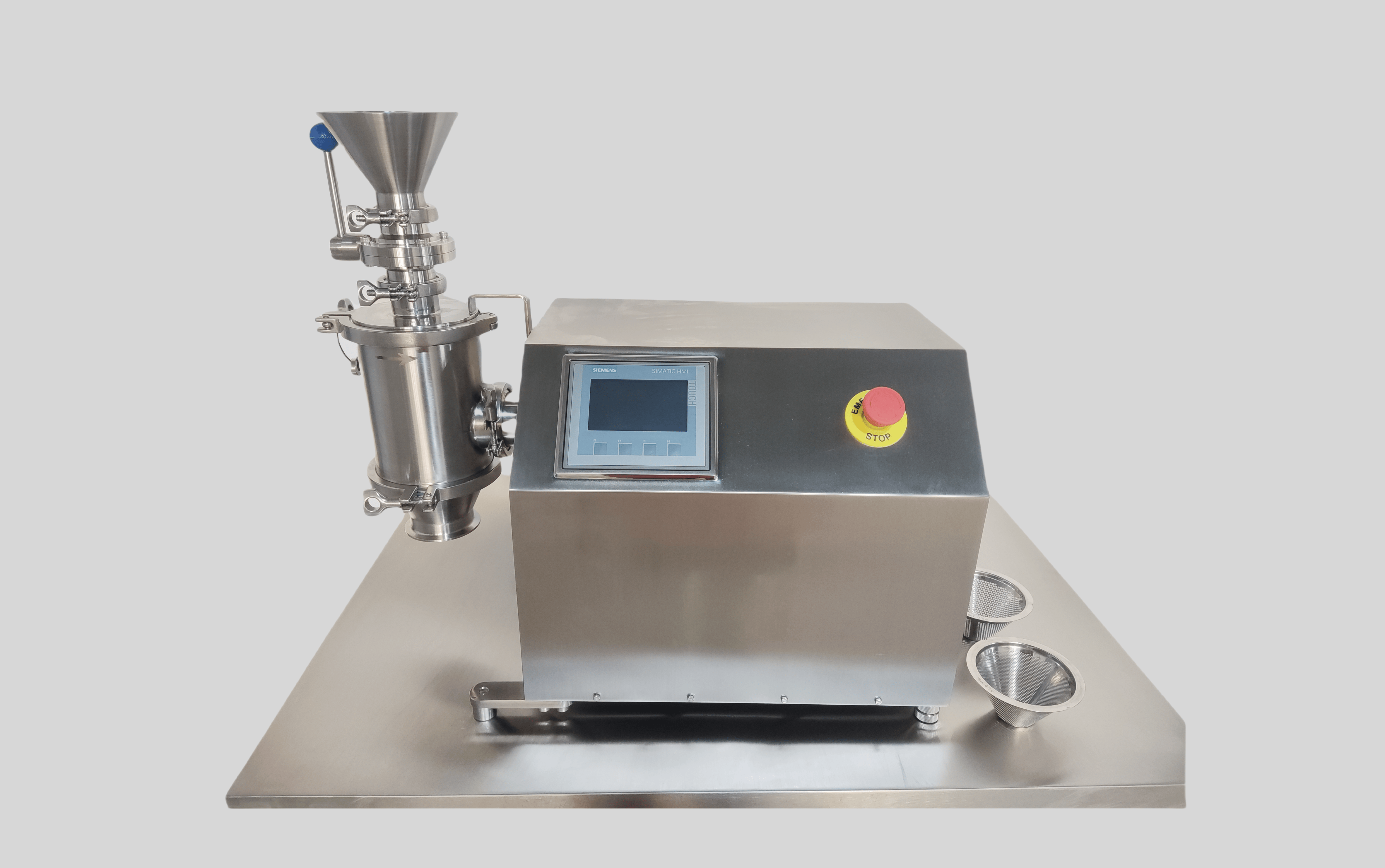

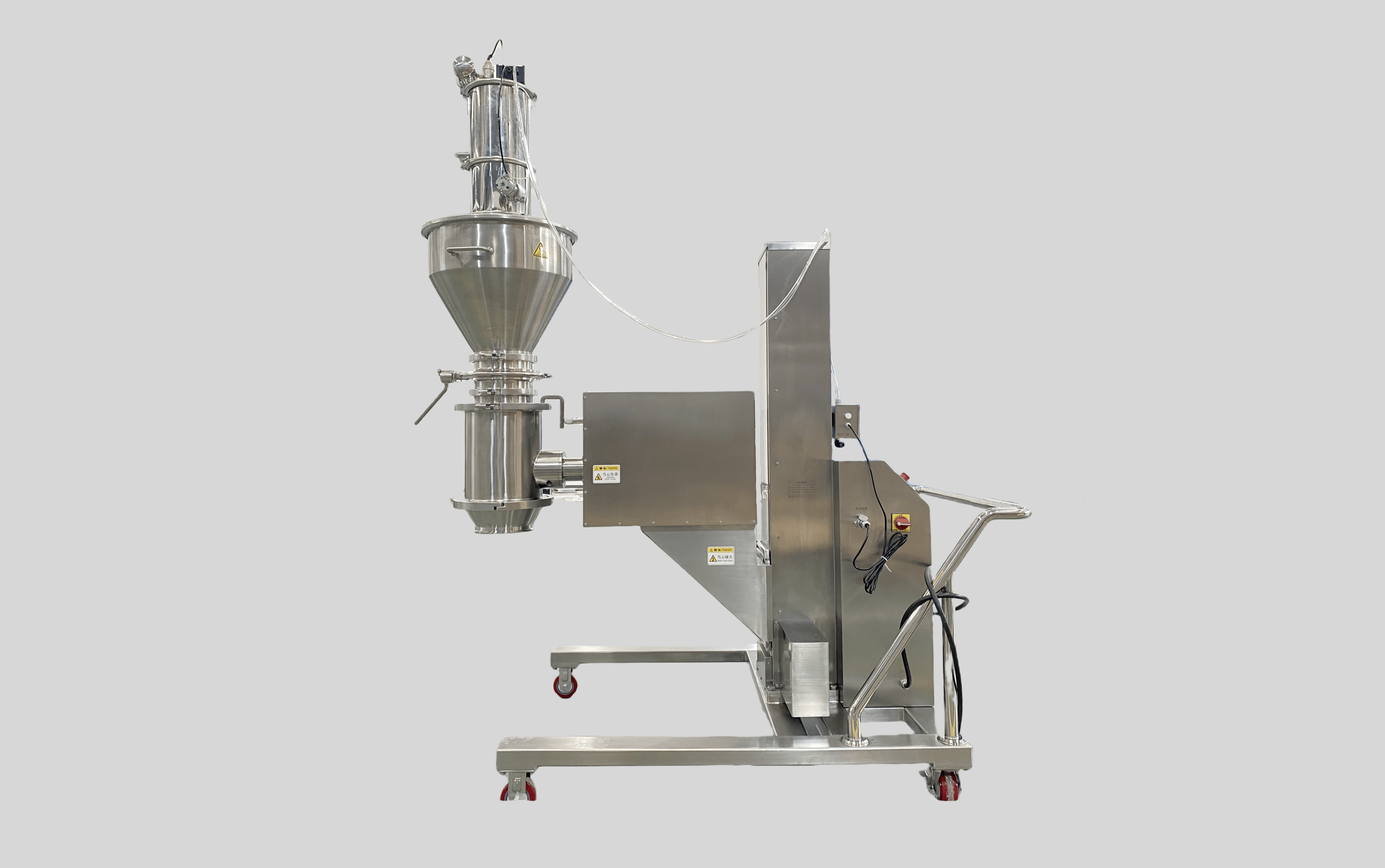

Mobile Whole Grain Machine (Explosion-proof) ZLJ-100-EX

Working principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the block-like materials under the pressure of the rotor, passing through the screen holes, and the finished granules are instantly discharged. It features low heat generation, high efficiency, and good quality. Variable frequency speed regulation allows for adjustable main shaft speed with a wide range. The bottom drive ensures smooth feeding.

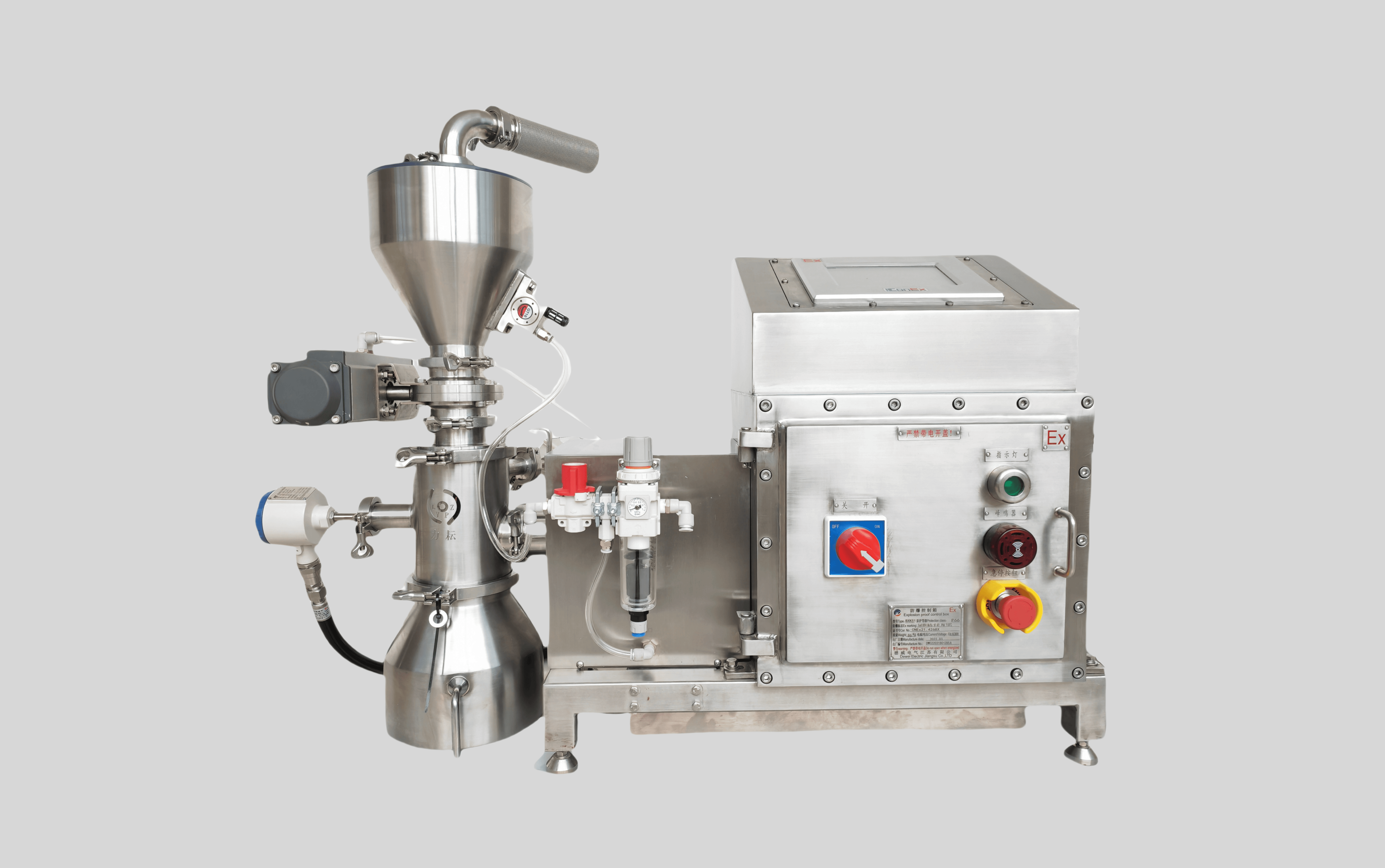

Chongqing Liweikang's self-designed whole grain machine's right-angle transmission system and shaft sealing technology greatly reduces the risk of material contamination.

Mobile Whole Grain Machine (Explosion-proof) ZLJ-270-Y-EX

Working principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the lump-like materials under the rolling pressure of the rotor, passing through the screen holes. The finished granules are instantly discharged, with low heat generation, high efficiency, and good quality.

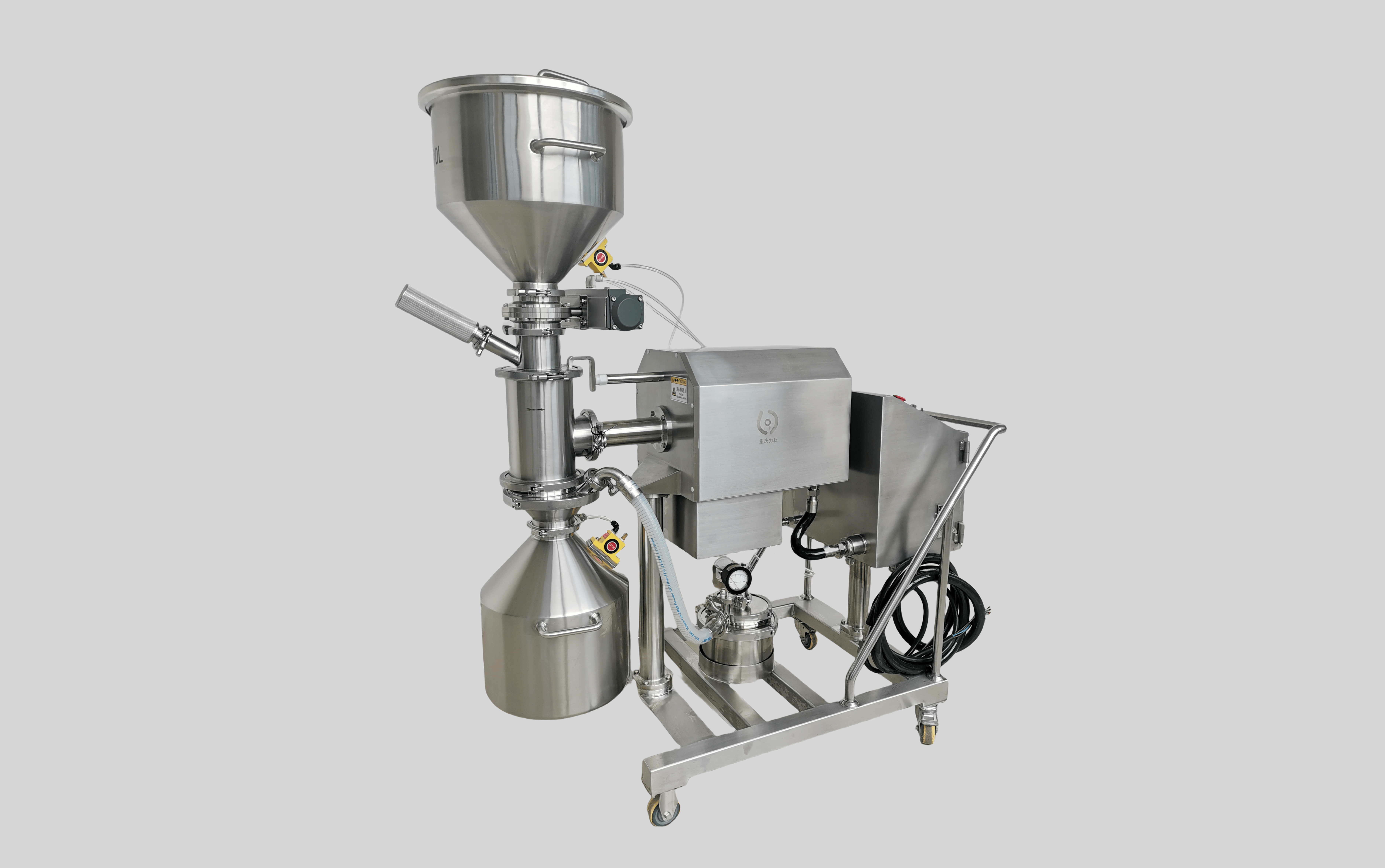

Electric Grain Elevator ZLJ-208-Y

Working principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the lump-like materials under the rolling pressure of the rotor, passing through the screen holes. Finished granules are instantly discharged, with low heat generation, high efficiency, and good quality.

Equipped with an electric lifting function for efficient and convenient operation.

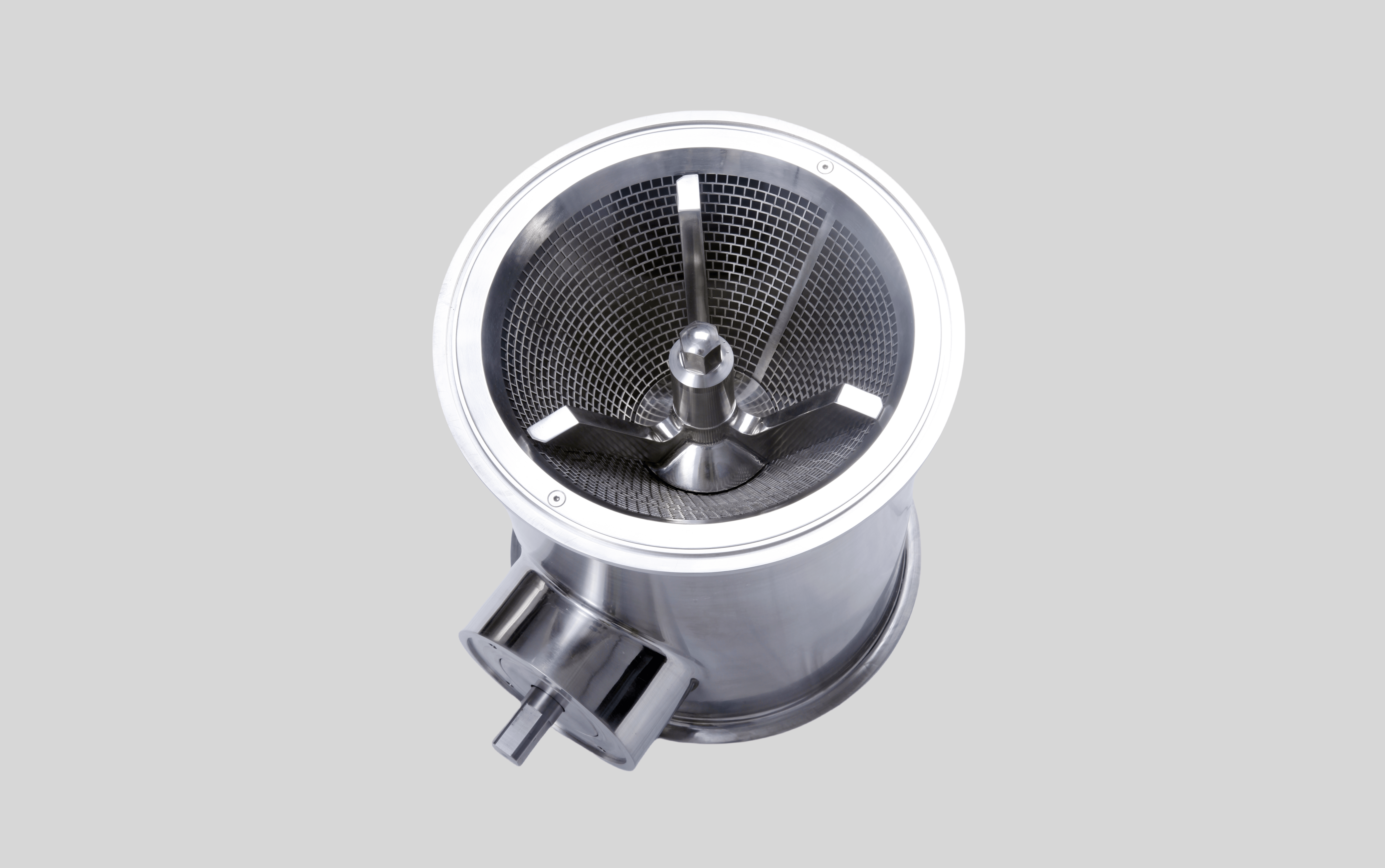

Three types of whole-grain knives: round whole-grain knife, square whole-grain knife, and toothed whole-grain knife, suitable for various materials with different properties.

Working principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the lump-like materials under the rolling pressure of the rotor, passing through the screen holes. The finished granules are instantly discharged, with low heat generation, high efficiency, and good quality.

Mobile whole grain machine (explosion-proof) ZLJ-140-Y-EX

Working principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the lump-like materials under the rolling pressure of the rotor, passing through the screen holes. The finished granules are instantly discharged, with low heat generation, high efficiency, and good quality.

Customizable mixing tanks of various models: single/double-layer, pneumatic, explosion-proof, electric heating

Electric Grain Elevator ZLJ-270-Y

Working principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the lump-like materials under the rolling pressure of the rotor, passing through the screen holes. Finished granules are instantly discharged, with low heat generation, high efficiency, and good quality. It is configured with an electric lifting function for quick and efficient height adjustment.

In a barrel with an "8"-shaped cross-section, the material is pushed and sheared by two meshing screws, and is uniformly and stably transported to the crushing chamber for crushing.

Contact Information

Telephone

/ TEL

Address

/ ADD

No. 2, No. 712 Xiangfu Avenue, Shuangfu Street, jiangjin district, Chongqing

Scan mobile websites