Oscillating Granulator

The YB-160 oscillating granulator is a specialized device that uses the forward and reverse rotation of a rotating drum to force a wet powder mixture through a screen to produce granules. It is an innovative and optimized granulator designed by our company to meet the needs of our customers and to seamlessly connect with highly efficient wet granulation processes.

Key words: liquid particle handling system solid particle handling system pharmaceutical preparation intelligent equipment equipment intelligent control technology

Classification:

Hotline:

Oscillating Granulator

I.Equipment Introduction

1. Equipment Description

The YB-160 type oscillating granulator is a special equipment that uses the forward and reverse rotation of a rotating drum to force a wet powder mixture through a screen to produce granules. It is an innovative and optimized granulator designed by our company to meet the needs of customers and the docking of highly efficient wet granulation at a low position. This machine features a simple and reasonable structure, full energy utilization, advanced granulation method, and high efficiency and energy saving. One machine has both granulation and pulverization functions, achieving the purpose of multi-functionality. It is suitable for granules of various specifications in the pharmaceutical, chemical, and food industries. Users consistently report that this machine produces uniform granules with a low powder content, is easy to operate, has a long service life, and meets GMP standards. Parts in contact with materials are made of 316L stainless steel.

2. Outstanding Features

(1) This machine adopts a horizontal design, making it stable in operation and easy to maintain.

(2) The motor and gearbox are heavy-duty and sturdy, the operation is simple, the operation is stable, and it is equipped with a large-capacity hopper.

(3) Various screen specifications can be selected by the user. The device is secured with two steel pipes, making installation and removal easy. Tightening and loosening are controlled by a fine-toothed wheel, allowing for adjustment.

(4) The inlet and outlet are processed with thick plate arcs to prevent material blockage.

(5) It features a beautiful and generous appearance, simple operation, easy cleaning, and low energy consumption.

3. Working Principle

Mechanical transmission causes the drum to reciprocate, extruding the material from the screen to achieve pulverization and granulation or rapid granulation.

II.Equipment Configuration Table

|

Serial Number |

Name |

Specification Model |

Material |

Quantity |

Remarks |

|

1 |

Frame |

40*40 Angle steel, 12mm plate |

Carbon steel |

1 set |

|

|

2 |

Cover Plate |

2mm |

SUS304 |

1 set |

|

|

3 |

Granulation Device |

18mm |

SUS304 |

1 set |

|

|

4 |

Flange |

18mm |

SUS304 |

1 set |

|

|

5 |

Motor |

4Kw |

Q235 |

1 unit |

|

|

6 |

Drum |

YB160 |

SUS304 |

1 set |

|

|

7 |

Discharge port |

Standard Configuration |

SUS304 |

1 set |

|

|

8 |

Reducer |

YB160 |

Cast iron |

1 set |

|

|

11 |

Bearing |

|

Bearing steel |

1 set |

|

III. Technical Parameters

|

Item |

Unit |

Parameter |

|

Production Capacity |

Kg/h |

≤200 (15 mesh screen, capacity is affected by material properties) |

|

Effective Length |

mm |

355 |

|

Forward and Reverse Speed |

r/min |

120 |

|

Swing Amplitude |

° |

360 |

|

Granulation Cutter Wheel Diameter |

mm |

160 |

|

Motor Power |

KW |

4 |

|

Power Supply |

V/Hz |

380/50 |

|

Maximum Motor Speed |

r/min |

1450 |

|

Installed Capacity |

kw |

4 |

|

External Dimensions |

mm |

1350*555*1295 |

|

Weight |

Kg |

220 |

Prev

None

Next

More products

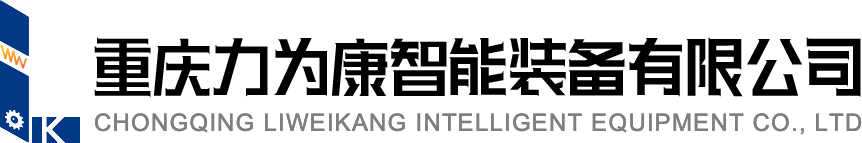

Desktop whole grain machine ZLJ-100

Working principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the block-like materials under the pressure of the rotor, passing through the screen holes, and the finished granules are instantly discharged. It features low heat generation, high efficiency, and good quality. Variable frequency speed regulation allows for adjustable main shaft speed with a wide range. The bottom drive ensures smooth feeding.

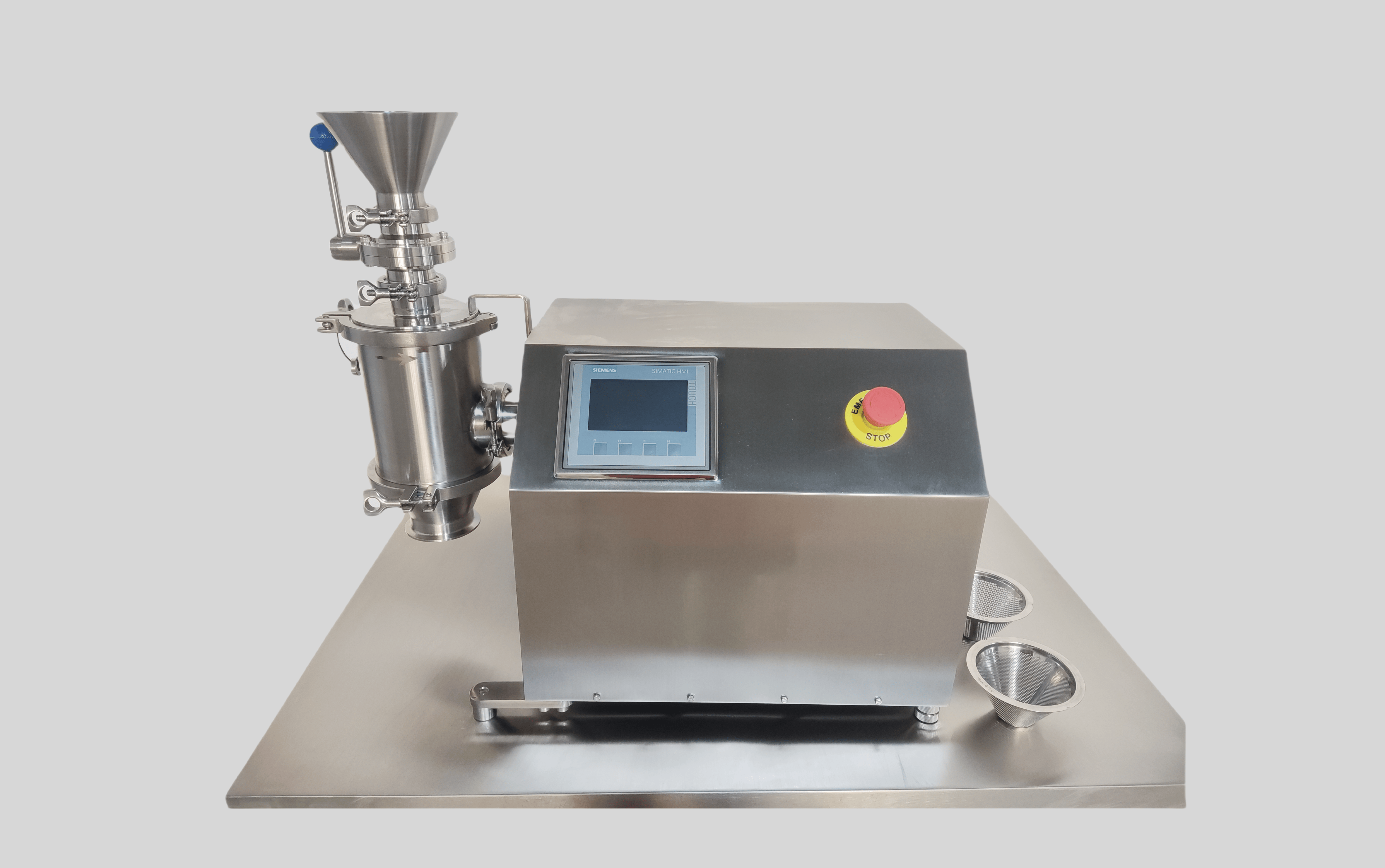

Mobile whole grain machine ZLJ-208-Y

Working principle: This machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the block-like materials under the pressure of the rotor, passing through the screen holes. The finished granules are discharged instantly, resulting in less heat generation, high efficiency, and good quality. It adopts frequency conversion speed regulation, the main shaft speed is adjustable, and the range is wide. The lower drive ensures smooth feeding. The parts of the machine that contact the materials and the external parts are made of high-quality stainless steel with a polished surface. It can be used with wet granulation machines and fluidized bed drying equipment.

Mobile Whole Grain Machine (Explosion-proof) ZLJ-100-EX

Working principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the block-like materials under the pressure of the rotor, passing through the screen holes, and the finished granules are instantly discharged. It features low heat generation, high efficiency, and good quality. Variable frequency speed regulation allows for adjustable main shaft speed with a wide range. The bottom drive ensures smooth feeding.

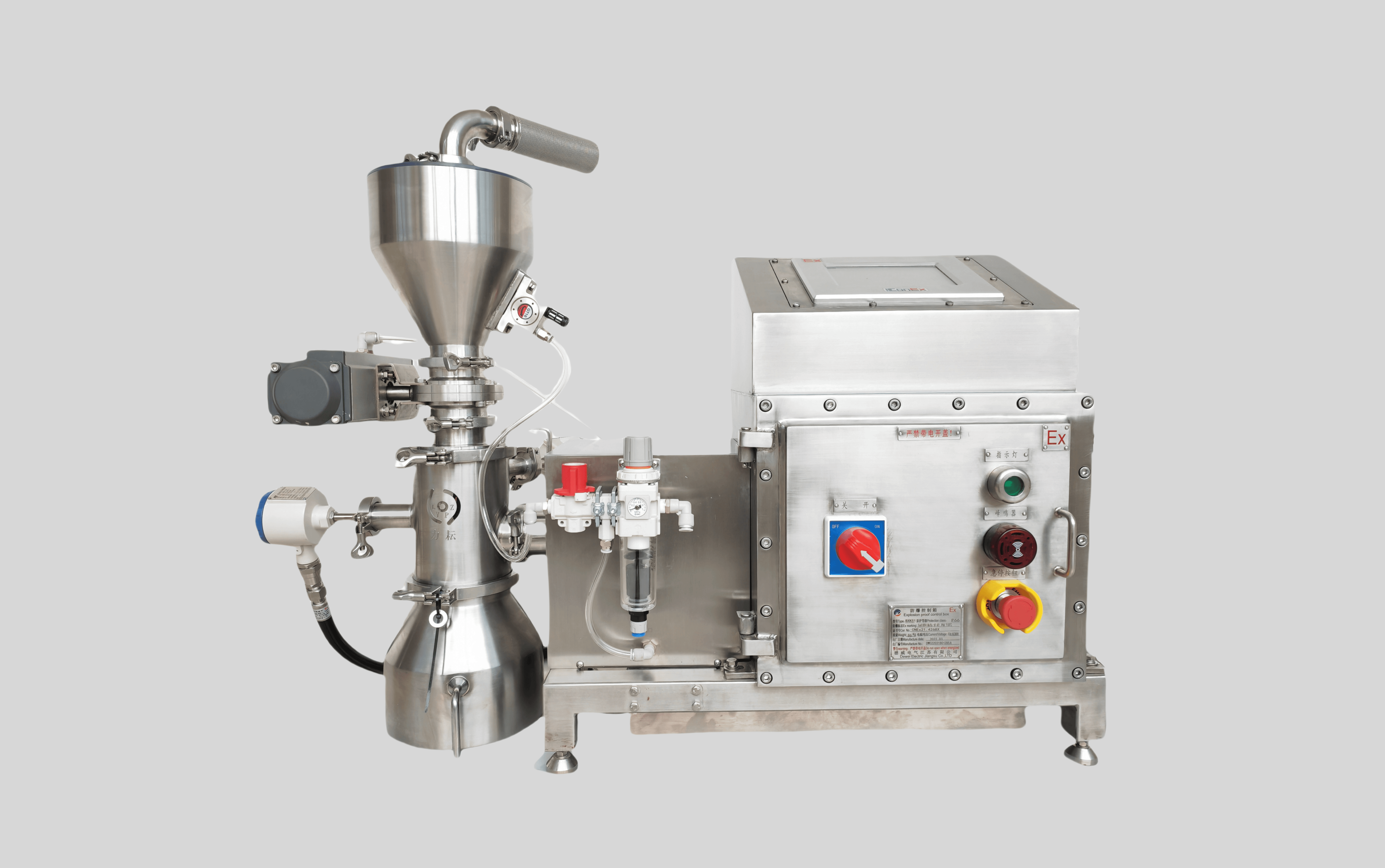

Chongqing Liweikang's self-designed whole grain machine's right-angle transmission system and shaft sealing technology greatly reduces the risk of material contamination.

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 023-65663700

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Contact Information

Telephone

/ TEL

Address

/ ADD

No. 2, No. 712 Xiangfu Avenue, Shuangfu Street, jiangjin district, Chongqing

Scan mobile websites