Extrusion Rounding Machine

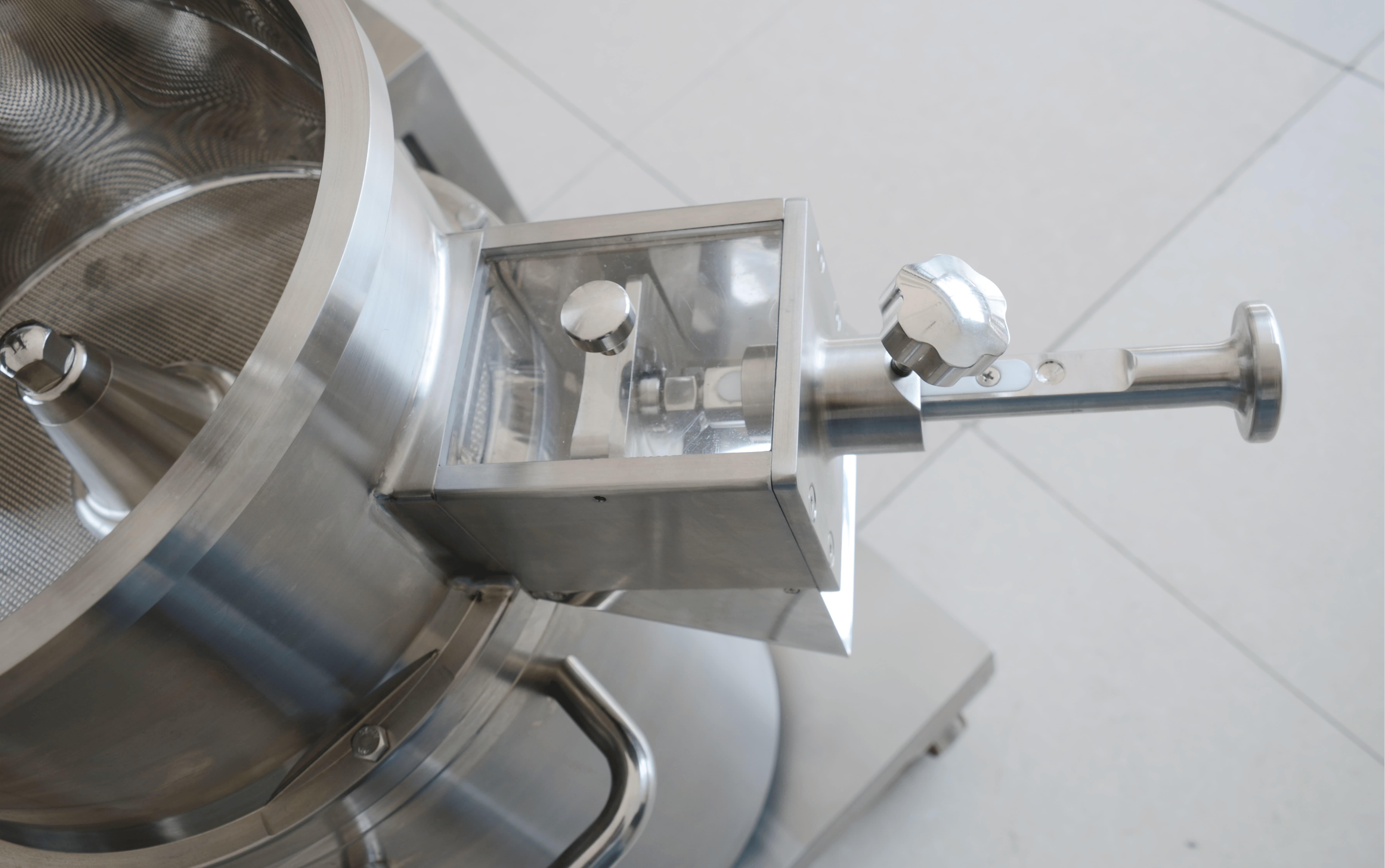

The prepared microgranules can be further compressed into tables or filled into empty capsules.

Classification:

Email:

export@cqlypz.com

Extrusion Rounding Machine

Feature

- High Yield

- Uniform and Efficient Extrusion

- Three Types of Rotating Discs(Plain Disc, Orthogonal Toothed Disc, Divergent Toothed Disc Optional)

- Built-In Cooling Channels

- Modular Screw Design

- No Dust leakage

Introduction

The wet raw materials are conveyed and extruded by a rotating screw into a die head, where the material is pressed into stands and then rounded into dense spherical granules by a high-speed rotating toothed disc.

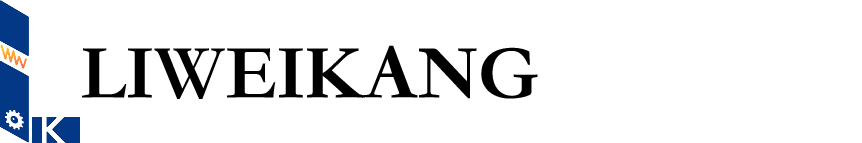

Spherical extrusion belt cooling device

Spherical extrusion

lateral extrusion

End face extrusion

Feed bin

Extrusion mechanism

extrusion screw

Accessory placement rack

Toothed disc

Smooth disc

discharge mechanism

micro pills

extruder | |||

Item | Unit | JCD-50 | JCD-100 |

Capacity | kg/h | ≤10 | ≤50 |

Minimum feeding amount | kg | 0.12 | 0.5 |

Extrusion mode |

| Single screw spherical extrusion/lateral extrusion/end face extrusion | |

Screw diameter | mm | 50 | 100 |

Mesh diameter | mm | spherical extrusion:Φ0.5--Φ3.0 lateral extrusion/end face extrusion:Φ0.3--Φ3.0 | |

Speed | r/min | 10--80 |

|

Power of motor | kw | 0.75 | 2.2 |

spheronizator | |||

Item | Unit | GY-315 | GY-700 |

feeding amount | kg/batch | 0.1--1.0 | 1.0--10.0 |

Pellets diameter | mm | 0.2-2 | |

Turntable diameter | mm | 315 | 700 |

Turntable form | mm | Toothed discs and smooth discs are optional | |

Speed | r/min | 150--2000 | 100--700 |

Power of motor | kw | 2.2 | 5.5 |

| Qualified yield | ≥95% | ||

| Noise | <75 | ||

| Dimension | mm | 1300*550*1380 | 1700*1000*1950 |

| Weight | kg | ≈280 | ≈980 |

Due to equipment updates or upgrades, all the above data shall be subject to the final signed contract.

Prev

Prev

Rotary Extrusion Machine

More products

Pulverization of active pharmaceutical ingredients(APIs),including hard,crystalline,and fibrous materials,as well as materials requiring very fine particle size.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

Hot melt spray congealing is a process in which molten material (hot melt) is broken into fine droplets by an atomizer (spray), rapidly cooled and solidified in a condensing medium (congealing), and finally transformed into solid particles with specific shapes and properties.

Utilizes vacuum fluidized bed technology and spray drying technology to achieve thermal and mass transfer, enabling multifunctional granulation, coating, and pelletizing of materials.

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 023-65663700

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Contact Information

Telephone

Address

No. 712-2 Xiangfu Avenue, Shuangfu Street, Jiangjin District, Chongqing, China

Scan mobile websites