fluidized bed(laboratorial)

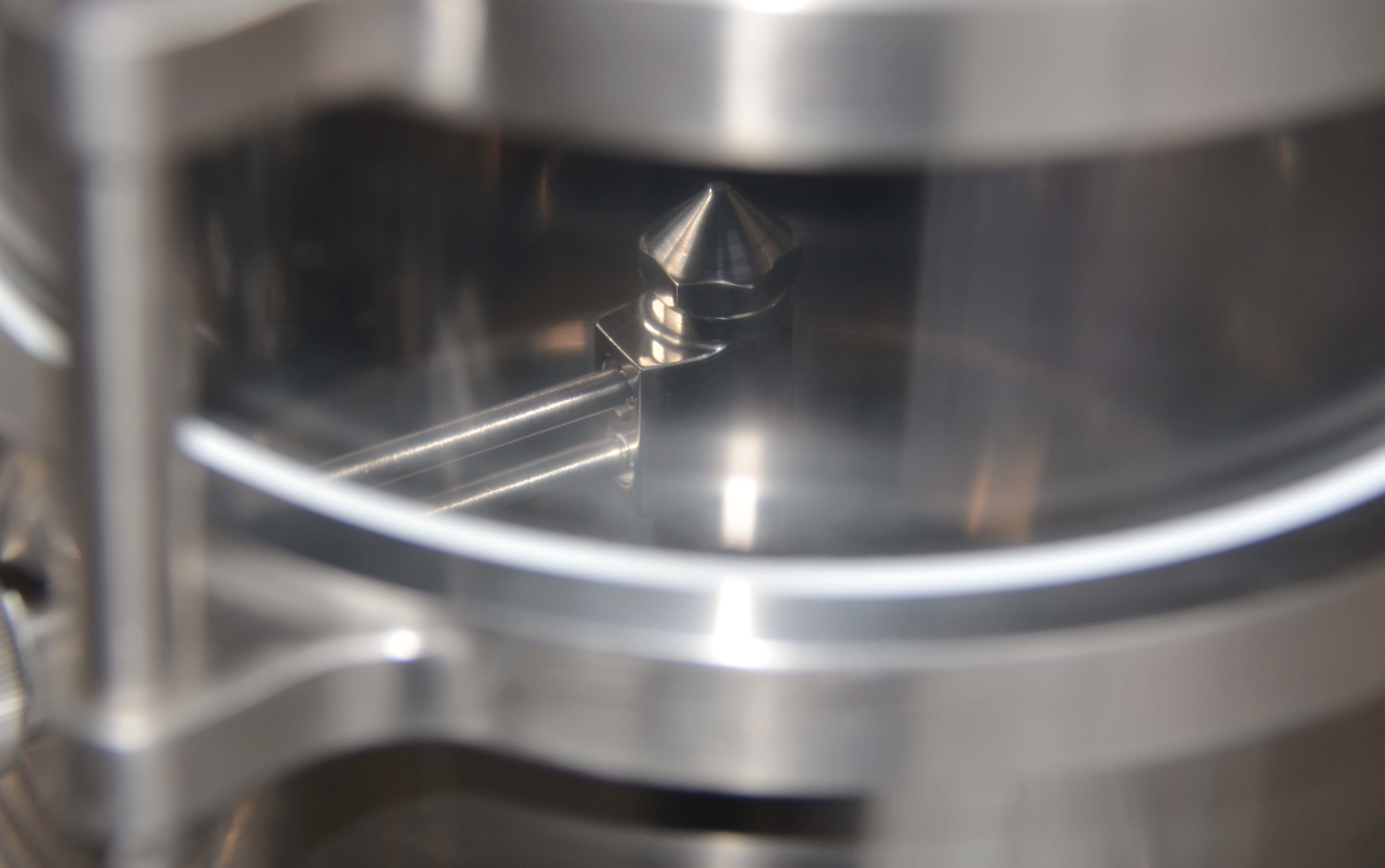

Utilizes vacuum fluidized bed technology and spray drying technology to achieve thermal and mass transfer, enabling multifunctional granulation, coating, and pelletizing of materials.

Classification:

Email:

export@cqlypz.com

fluidized bed(laboratorial)

- High efficiency

- Automation

- Independently designed spray gun

- Integrates mixing, granulation, coating, micro-pelletizing, and drying functions into a single system

- PLC-based program control

- Highly polished

- Excellent airtightness

Application

Powder materials can be processed straight into granules and pellets, and can undergo functional coating operations such as moisture-proofing, taste-masking, and sustained release.

main components

observation window

bottom spray

adjustment button

Bottom spray gun and distribution board

Top spray gun

Peristaltic pump delivery system

in-line sampling

Top spray granulation

model | Capacity (kg/batch) | Available capacity | Power (KW) | Temperature( ℃) | Optional | ||

Motor | Fan | Calorifier | |||||

MINI0.2 | top spray:0.05--0.25 Wurster bottom spray:0.03--0.2 | top spray:0.75 bottom spray:0.3 | 0.1 | 0.4 | 2 | room temperature--120 | Boiling drying + top spray granulation + Worcester column bottom spray + cyclone bottom spray + powder coating |

DPL-II | top spray:0.3--5 Wurster bottom spary:0.8--4 Side spray::0.8--1.5 | top spray:3.5 bottom spray:2 | 0.1&0.75 | 4 | 4.5 | room temperature--120 | |

DPL-20 | top spray:5--20 Wurster bottom spary:5-20 Side spray:0.5--10 | top spray:65 bottom spray:38 | 0.1 | 7.5 | 46 | room temperature--120 | |

DPL-60 | top spray:25--80 Wurster bottom spary:25-60 Side spray:5-25 | top spray:290 bottom spray:162 | 0.4 | 13.5 | 110 | room temperature--120 | |

DPL-120 | top spray:45--145 Wurster bottom spary: | top spray:545 bottom spray:384 | 0.4 | 18.5 | 166 | room temperature--120 | |

DPL-200 | top spray: 75--200 Wurster bottom spary:100--200 Side spray:25--60 | top spray:800 bottom spray:470 Side spray:250 | 0.4 | 30 | 221 | room temperature--120 | |

Prev

None

Next

More products

Pulverization of active pharmaceutical ingredients(APIs),including hard,crystalline,and fibrous materials,as well as materials requiring very fine particle size.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

Hot melt spray congealing is a process in which molten material (hot melt) is broken into fine droplets by an atomizer (spray), rapidly cooled and solidified in a condensing medium (congealing), and finally transformed into solid particles with specific shapes and properties.

Utilizes vacuum fluidized bed technology and spray drying technology to achieve thermal and mass transfer, enabling multifunctional granulation, coating, and pelletizing of materials.

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 023-65663700

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Contact Information

Telephone

Address

No. 712-2 Xiangfu Avenue, Shuangfu Street, Jiangjin District, Chongqing, China

Scan mobile websites