Rotary Extrusion Machine

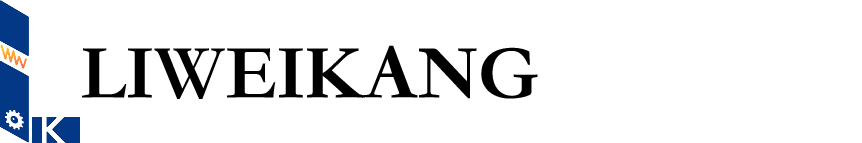

Materials are fed from the hopper and pass through a breaker knife into the extrusion chamber, where a feeding knife and an extrusion knife cooperate with low-shear technology to rotate and extrude the materials. The strands are then rounded into dense spherical microgranules by a high-speed rotating toothed disc.

Classification:

Email:

export@cqlypz.com

Rotary Extrusion Machine

- High Efficiency and Low Shear Force

- Small Mesh Size and High Open Area

- Low Heat Generation

- Applicable to Various Materials

- Easy To Assemble And Disassemble

- Twin-Knife Rotating Extrusion

Application

Poorly flowable, high-sugar, and heat-sensitive materials; granulation of traditional Chinese medicine and fine powders for pediatric use.

main components

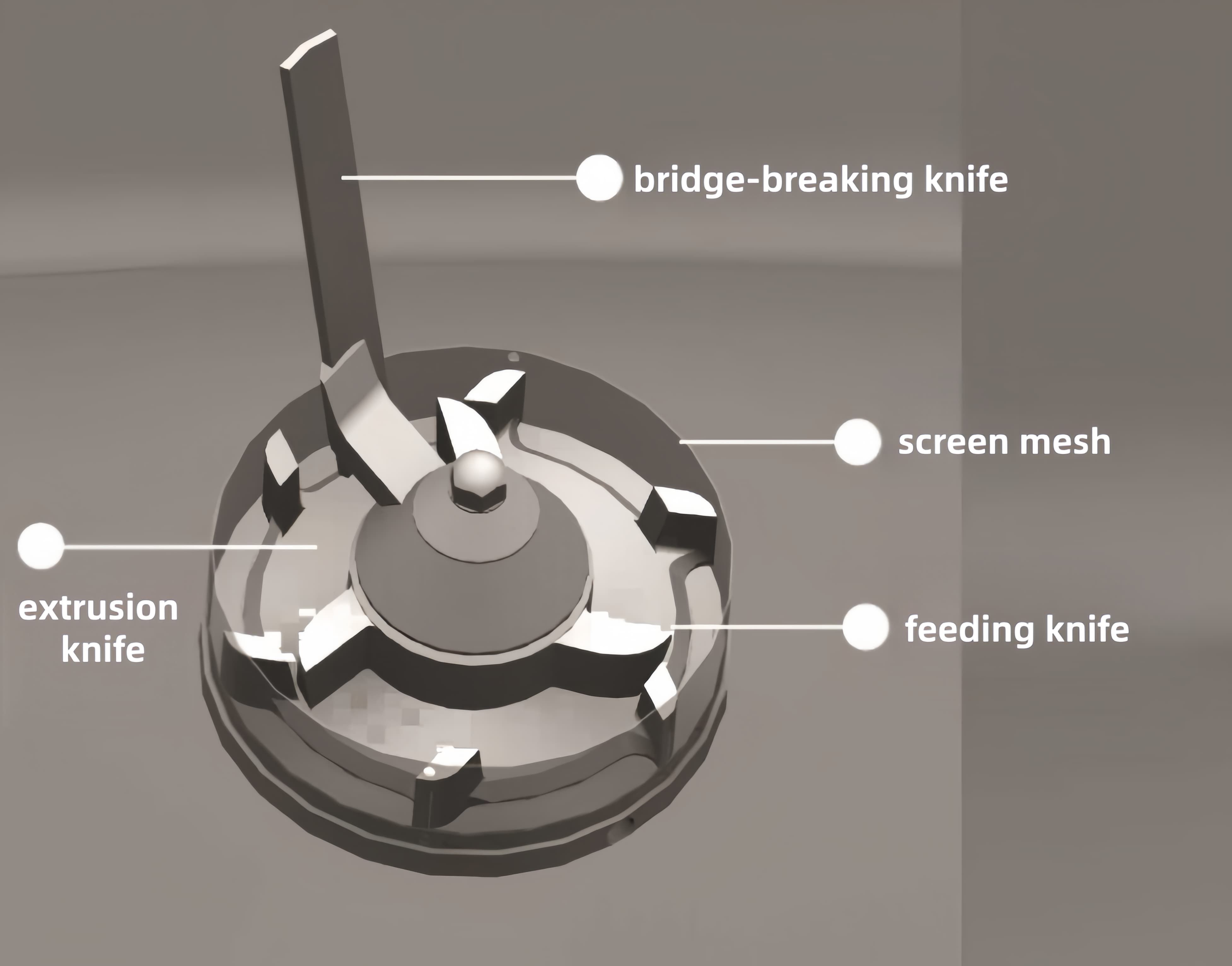

Extrusion blade

Feeding blade

Screen mesh

Material bin

Material extrusion

Material extrusion

dry material particles

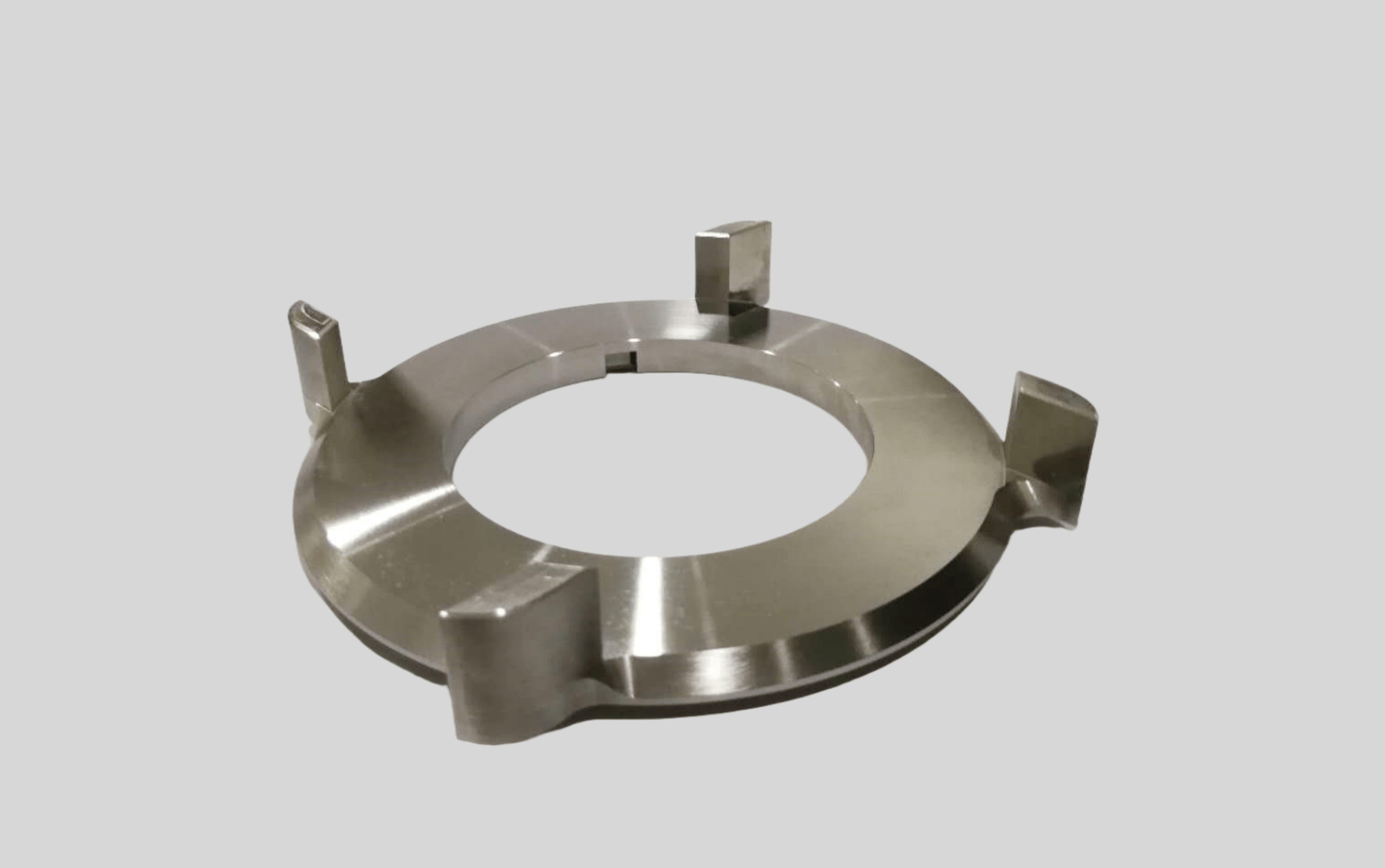

Wet material particles

Partial in production varieties

| Drug variety | dosage form | Drug variety | dosage form |

| Cefixime | Fine granule | Mesalazine | Granules, capsules |

| cefdinir | Fine granule | Aluminum magnesium aspirin | Tablets (granule tablets) |

| Cefteram pivoxil | Fine granule | Azithromycin | Fine granule |

| Cefaclor | Fine granule | Rivaroxaban | Fine granule |

| Cefotaxime | Granules | Amoxicillin | Fine granule |

| Cefditoren Pivoxil | Granules | Mycophenolate Sodium Enteric-coated Tablets | tablet |

| oseltamivir phosphate | Fine granule、Granules | Apricot shell | Granules (traditional Chinese patent medicines and simple preparations) |

| Omeprazole | Capsules (microspheres) | Six-Ingredient Rehmannia Pill | Pills (micro pills) |

| Compound paracetamol and alkylamine microspheres | Capsules (microspheres) | Orlistat | Capsule (material melting point 41 ℃) |

Item | Unit | model | ||

FF-100 | FF-140 | FF-220 | ||

Capacity | kg/h | ≤60 | ≤300 | ≤1200 |

Minimum feeding amount | kg | 0.5 | 0.5 | 1 |

Screen diameter | mm | 100 | 140 | 220 |

Hole diameter | mm | ≥Φ0.3 | ||

feeding motor | kw | 0.2 | 0.75 | 2.5 |

extrusion motor | kw | 0.4 | 2 | 5 |

Reducer deceleration ratio(feeding motor) | N/A | 20:1 | 25:1 | 20:1 |

Reducer deceleration ratio(extrusion motor) | N/A | 20:1 | 25:1 | 20:1 |

Maximum rated torque (feeding) | N.m | 16 | 60 | 238 |

Maximum rated torque(extrusion) | N.m | 25 | 238 | 479 |

Feeding speed | r/min | 10--150 | 10--120 | 10--100 |

Extrusion speed | r/min | 10--150 | 10--120 | 10--100 |

power | V/Hz | 220/50 | 380/50 | |

Material yield | N/A | ≥95% | ||

Dimension | mm | 1000*420*910 | 1350*520*1310 | 1500×600×1450 |

Weight | kg | ≈130 | ≈400 | ≈800 |

Rolling machine optional |

| GY-315 | GY-500/700 | GY-700/1000 |

Prev

None

Next

More products

Pulverization of active pharmaceutical ingredients(APIs),including hard,crystalline,and fibrous materials,as well as materials requiring very fine particle size.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

Hot melt spray congealing is a process in which molten material (hot melt) is broken into fine droplets by an atomizer (spray), rapidly cooled and solidified in a condensing medium (congealing), and finally transformed into solid particles with specific shapes and properties.

Utilizes vacuum fluidized bed technology and spray drying technology to achieve thermal and mass transfer, enabling multifunctional granulation, coating, and pelletizing of materials.

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 023-65663700

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Contact Information

Telephone

Address

No. 712-2 Xiangfu Avenue, Shuangfu Street, Jiangjin District, Chongqing, China

Scan mobile websites