Product Series

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

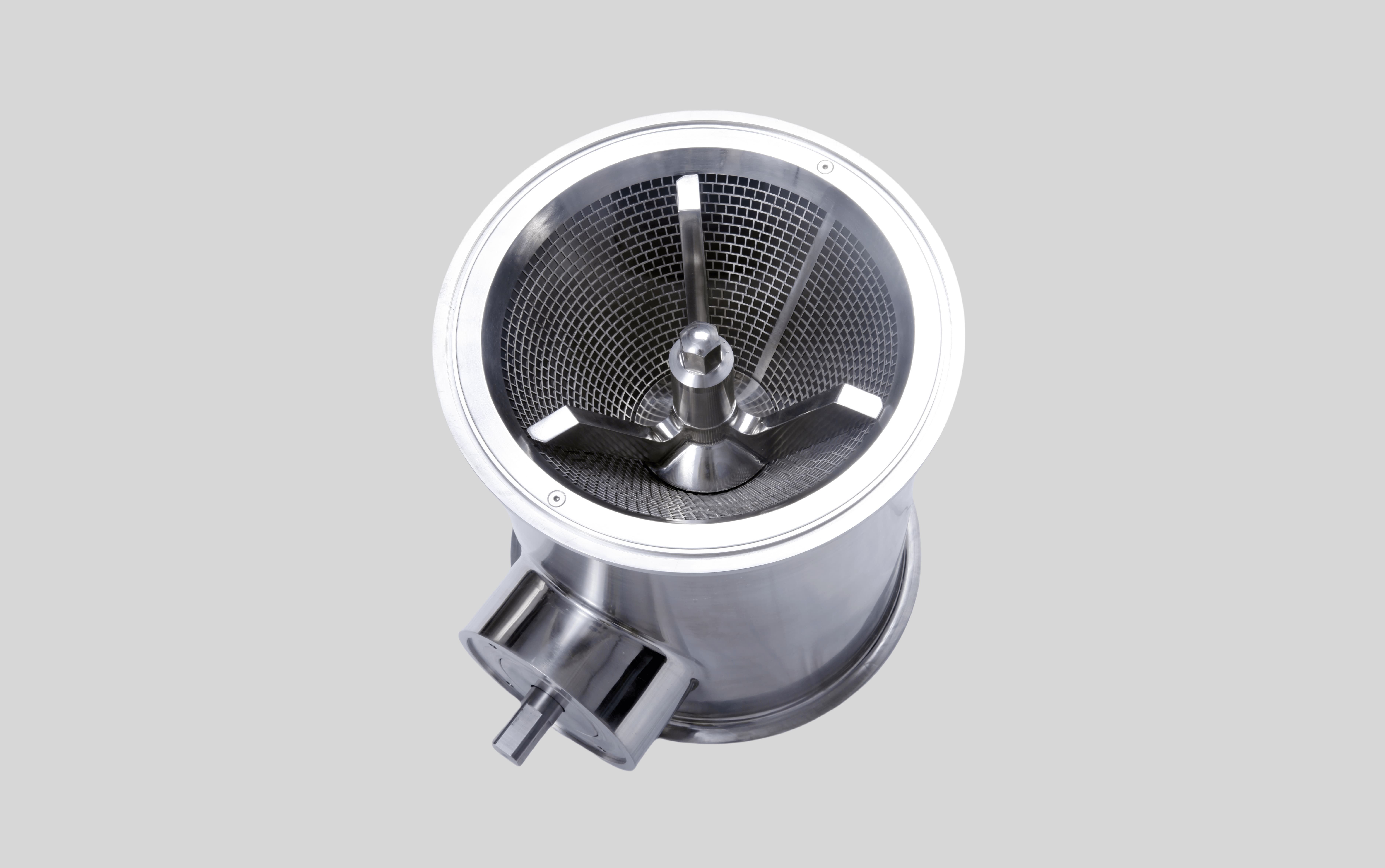

Chongqing Liweikang's self-designed cone mill transmission system and shaft sealing technology greatly reduces the risk of material contamination.

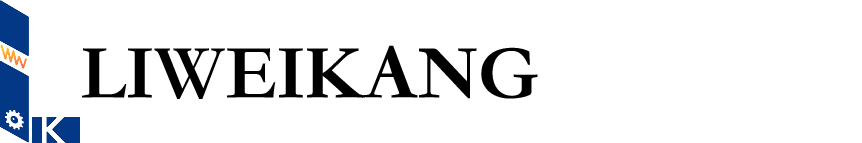

Three types of whole-grain knives: round whole-grain knife, square whole-grain knife, and toothed whole-grain knife, suitable for various materials with different properties.

Working principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the lump-like materials under the rolling pressure of the rotor, passing through the screen holes. The finished granules are instantly discharged, with low heat generation, high efficiency, and good quality.

Customizable mixing tanks of various models: single/double-layer, pneumatic, explosion-proof, electric heating

Electric lifting cone mill( ZLJ-270-Y)

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

In a barrel with an "8"-shaped cross-section, the material is pushed and sheared by two meshing screws, and is uniformly and stably transported to the crushing chamber for crushing.

Multifunctional Crushing/Milling/Sifting machine (S-LAB)

Switching Between Crushing, Milling, and Sieving functions by component replacement.

My company offers pneumatic butterfly valves in various specifications. Welcome to place your order!

The YB-160 oscillating granulator is a specialized device that uses the forward and reverse rotation of a rotating drum to force a wet powder mixture through a screen to produce granules. It is an innovative and optimized granulator designed by our company to meet the needs of our customers and to seamlessly connect with highly efficient wet granulation processes.

Contact Information

Telephone

Address

No. 712-2 Xiangfu Avenue, Shuangfu Street, Jiangjin District, Chongqing, China

Scan mobile websites