Electric Grain Elevator ZLJ-270-Y

Working principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the lump-like materials under the rolling pressure of the rotor, passing through the screen holes. Finished granules are instantly discharged, with low heat generation, high efficiency, and good quality. It is configured with an electric lifting function for quick and efficient height adjustment.

Key words: liquid particle handling system solid particle handling system pharmaceutical preparation intelligent equipment equipment intelligent control technology

Classification:

Hotline:

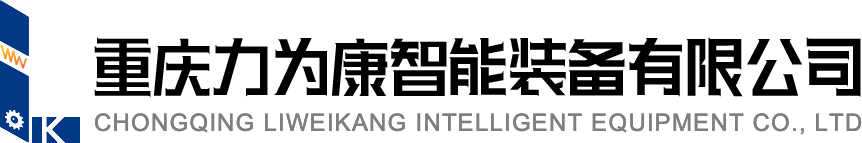

Electric Grain Elevator ZLJ-270-Y

Applications:Primarily for wet granulation and spray granulation, this equipment processes agglomerated materials and substandard tablets, enabling size adjustment according to granularity requirements. It can also be used for the crushing and regranulation of food, biscuit crumbs for recycling, and other coarse raw materials. It is an ideal device for handling low-viscosity blocky, gum-like, and moist materials.

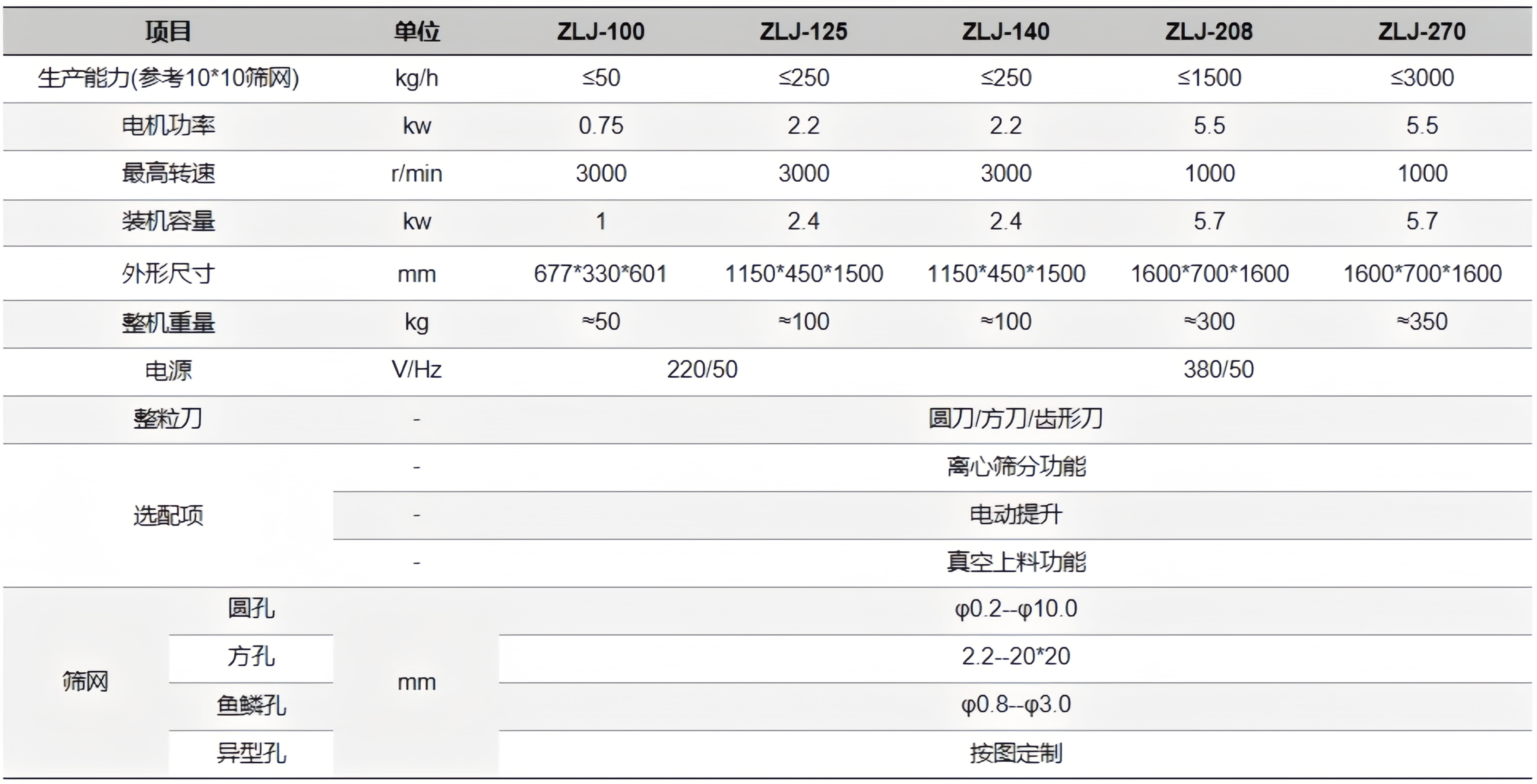

Technical Parameters:

*Our company reserves the right to interpret the product description on this page. Due to product upgrades and updates, technical parameters are subject to change.

Prev

Multifunctional whole grain crushing and screening integrated machine S-LAB

More products

Desktop whole grain machine ZLJ-100

Working principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the block-like materials under the pressure of the rotor, passing through the screen holes, and the finished granules are instantly discharged. It features low heat generation, high efficiency, and good quality. Variable frequency speed regulation allows for adjustable main shaft speed with a wide range. The bottom drive ensures smooth feeding.

Mobile whole grain machine ZLJ-208-Y

Working principle: This machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the block-like materials under the pressure of the rotor, passing through the screen holes. The finished granules are discharged instantly, resulting in less heat generation, high efficiency, and good quality. It adopts frequency conversion speed regulation, the main shaft speed is adjustable, and the range is wide. The lower drive ensures smooth feeding. The parts of the machine that contact the materials and the external parts are made of high-quality stainless steel with a polished surface. It can be used with wet granulation machines and fluidized bed drying equipment.

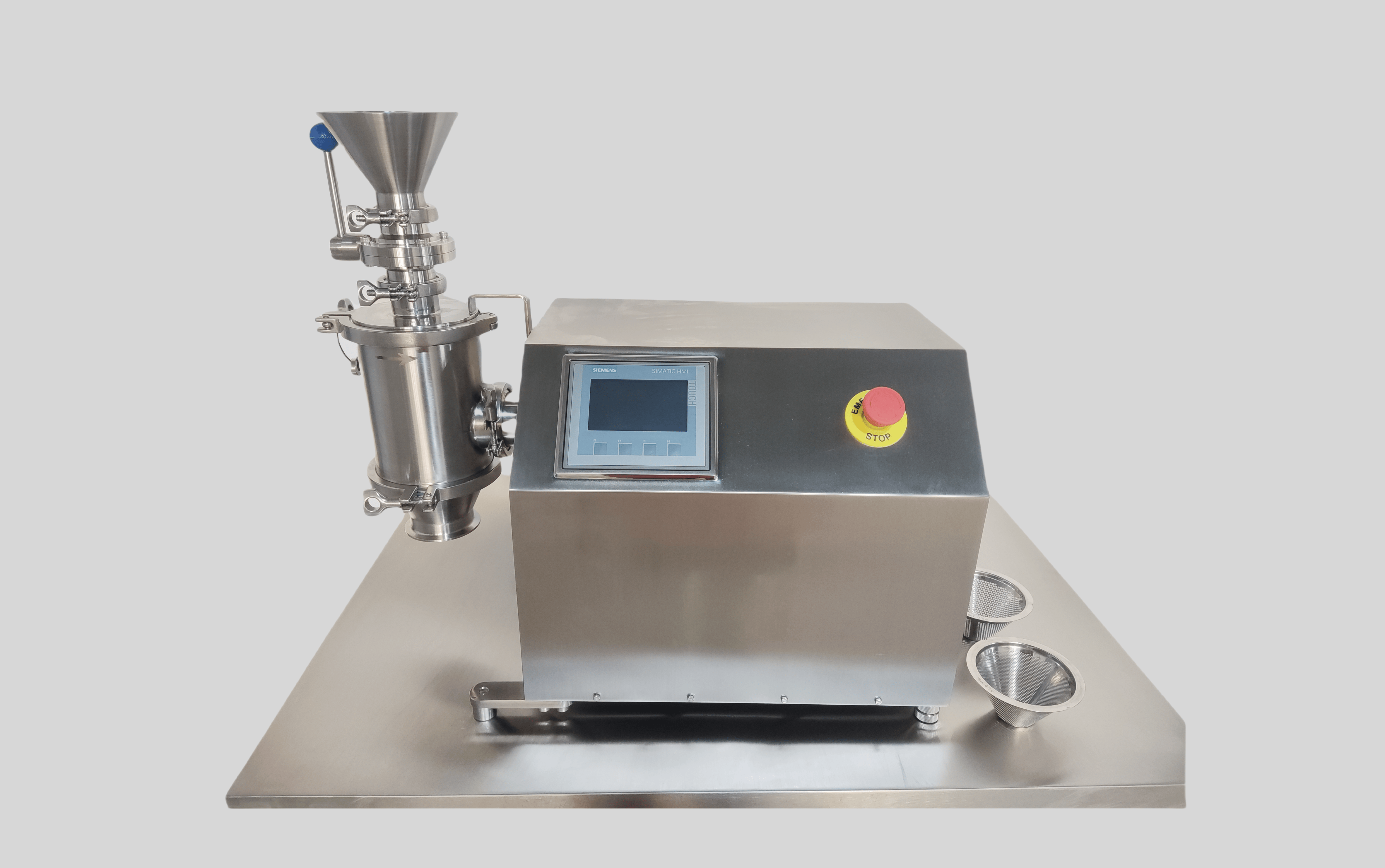

Mobile Whole Grain Machine (Explosion-proof) ZLJ-100-EX

Working principle: The whole grain machine utilizes the high-speed relative motion between the rotor and the screen to quickly granulate the block-like materials under the pressure of the rotor, passing through the screen holes, and the finished granules are instantly discharged. It features low heat generation, high efficiency, and good quality. Variable frequency speed regulation allows for adjustable main shaft speed with a wide range. The bottom drive ensures smooth feeding.

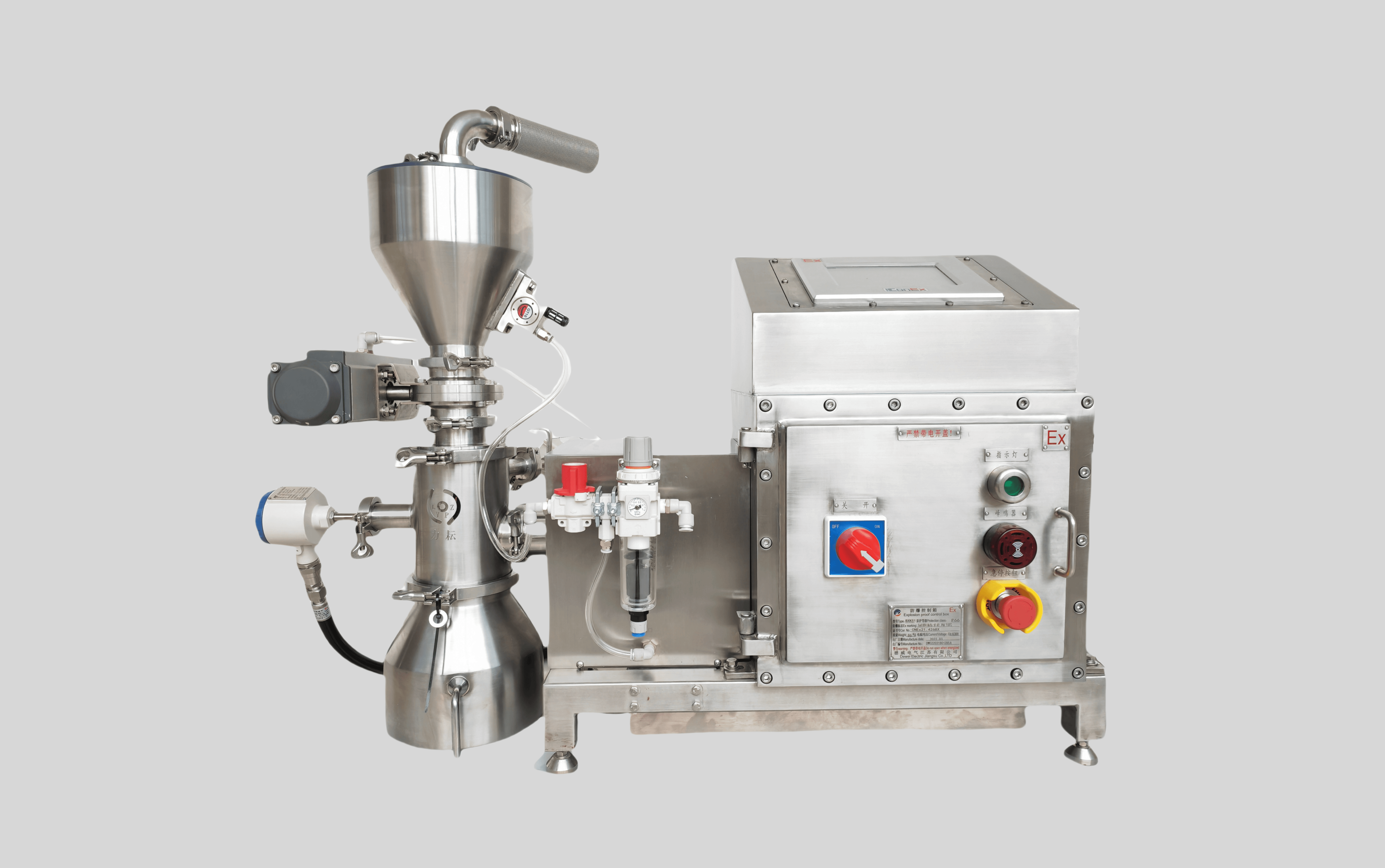

Chongqing Liweikang's self-designed whole grain machine's right-angle transmission system and shaft sealing technology greatly reduces the risk of material contamination.

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 023-65663700

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Contact Information

Telephone

/ TEL

Address

/ ADD

No. 2, No. 712 Xiangfu Avenue, Shuangfu Street, jiangjin district, Chongqing

Scan mobile websites