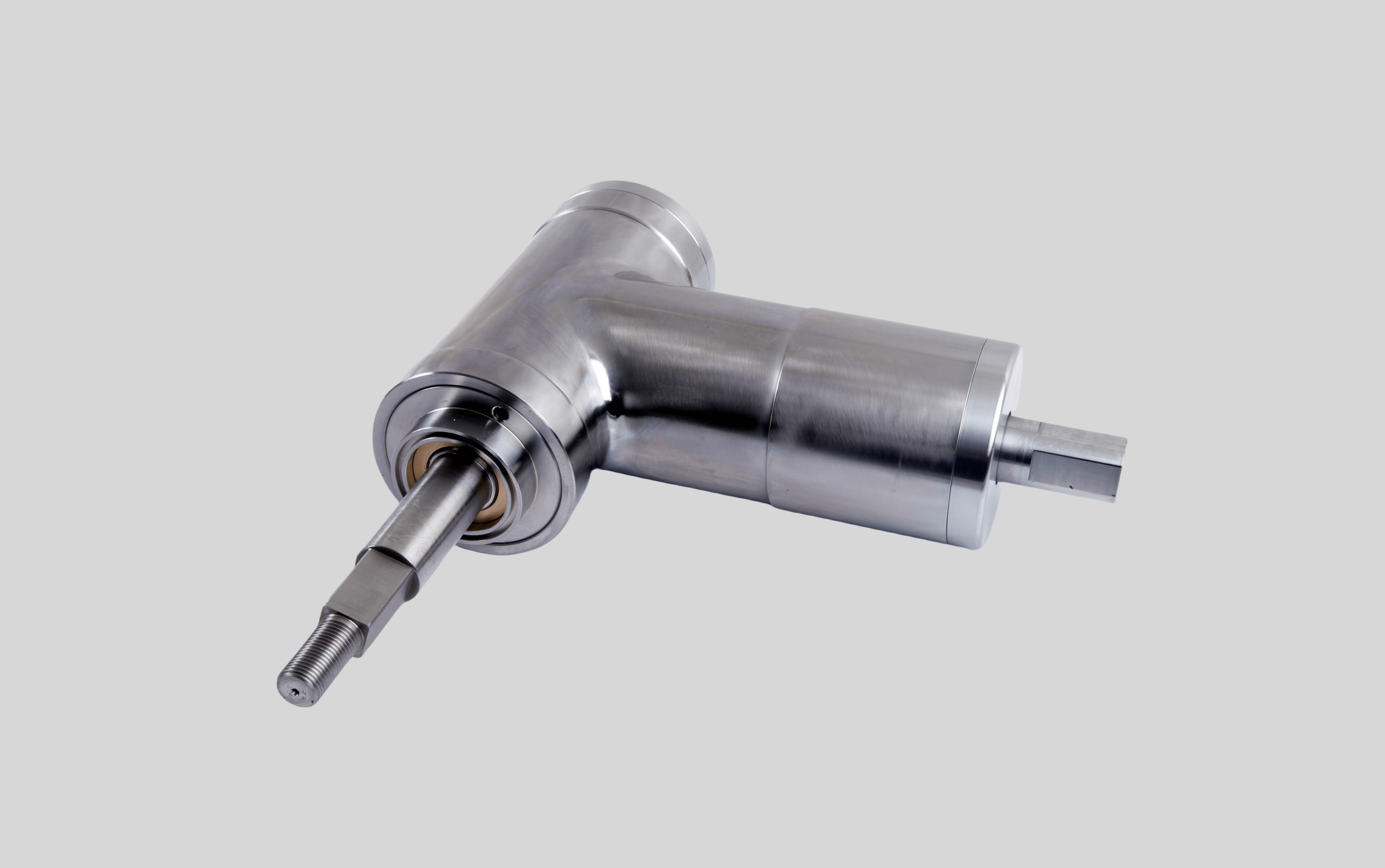

Rotary swaging and extrusion rounding machine

Product Overview: Utilizing twin-blade rotary extrusion, the feed blade and extrusion blade, combined with low-shear technology, reduce energy consumption and temperature rise, enabling adaptability to a wide range of materials and making it ideal for processing sensitive materials. Multiple screen models are available to optimize particle size, surface quality, and particle size distribution. Suitable for batch and continuous production. Modular design facilitates cleaning.

Classification:

Email:

Rotary swaging and extrusion rounding machine

Technical Features:

★ Employs a dual-blade rotary extrusion system. The feed blade and extrusion blade, combined with low-shear technology, minimize energy consumption and temperature rise.

★ A full range of screen mesh Models and Specifications are available, with pore sizes as small as φ0.3mm and high open area (>20%).

★ High efficiency, low-shear technology with precise torque monitoring; smooth and efficient extrusion.

★ Gentle extrusion with low heat generation, adaptable to a wide range of materials, making it ideal for processing heat-sensitive materials.

★ Quick-release connections for simple, fast assembly, disassembly, and cleaning.

Application Range:

★Suitable for heat-sensitive materials

★Suitable for high-sugar content materials

★Suitable for traditional Chinese medicine granulation

★Suitable for extrusion pelletizing

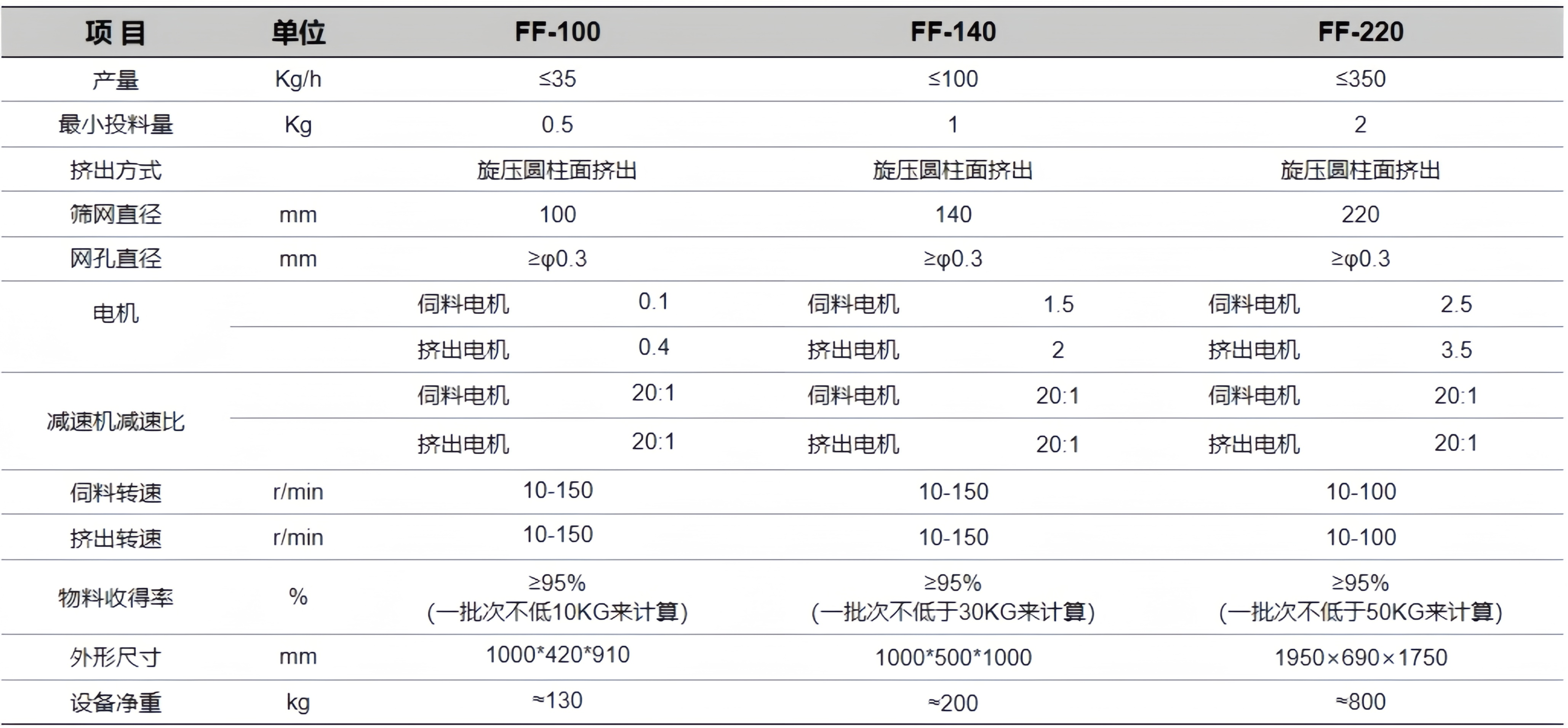

Technical Parameters:

*The company reserves the right to interpret the product Description on this page. Technical parameters are subject to change due to product upgrades and updates.

Prev

Prev

FF-100 Rotary Extrusion Machine

More products

Pulverization of active pharmaceutical ingredients(APIs),including hard,crystalline,and fibrous materials,as well as materials requiring very fine particle size.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

Chongqing Liweikang's self-designed whole grain machine's right-angle transmission system and shaft sealing technology greatly reduces the risk of material contamination.

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 023-65663700

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Contact Information

Telephone

/ TEL

Address

/ ADD

No. 2, No. 712 Xiangfu Avenue, Shuangfu Street, jiangjin district, Chongqing

Scan mobile websites