Wet granulator

Mixing, Moistening, and Granulating of Powder Materials, Widely Used in Pharmaceuticals, Food, and Chemical Industries

Classification:

Email:

Wet granulator

Feature

- High Efficiency

- Uniform mixing in a short time

- Uniform Atomization

- Intelligent Control Interface

- Mixing Bowls of Different Specification to Meet Batch Requirements

- Easy to Assemble and Disaseemble

- Compatible with Mobile Granulator

Introduction

Powdered materials in a sealed container are brought into a semi-fluid state by the rotation of the mixing paddle, ensuring thorough mixing. At the same time, binder and an appropriate amount of water are added, allowing the materials to form a moist, soft mass. The mass isthen cut by the high-speed rotation of a horizontal cutter, and subsequently processed through a granulator to produce uniform wet granules.

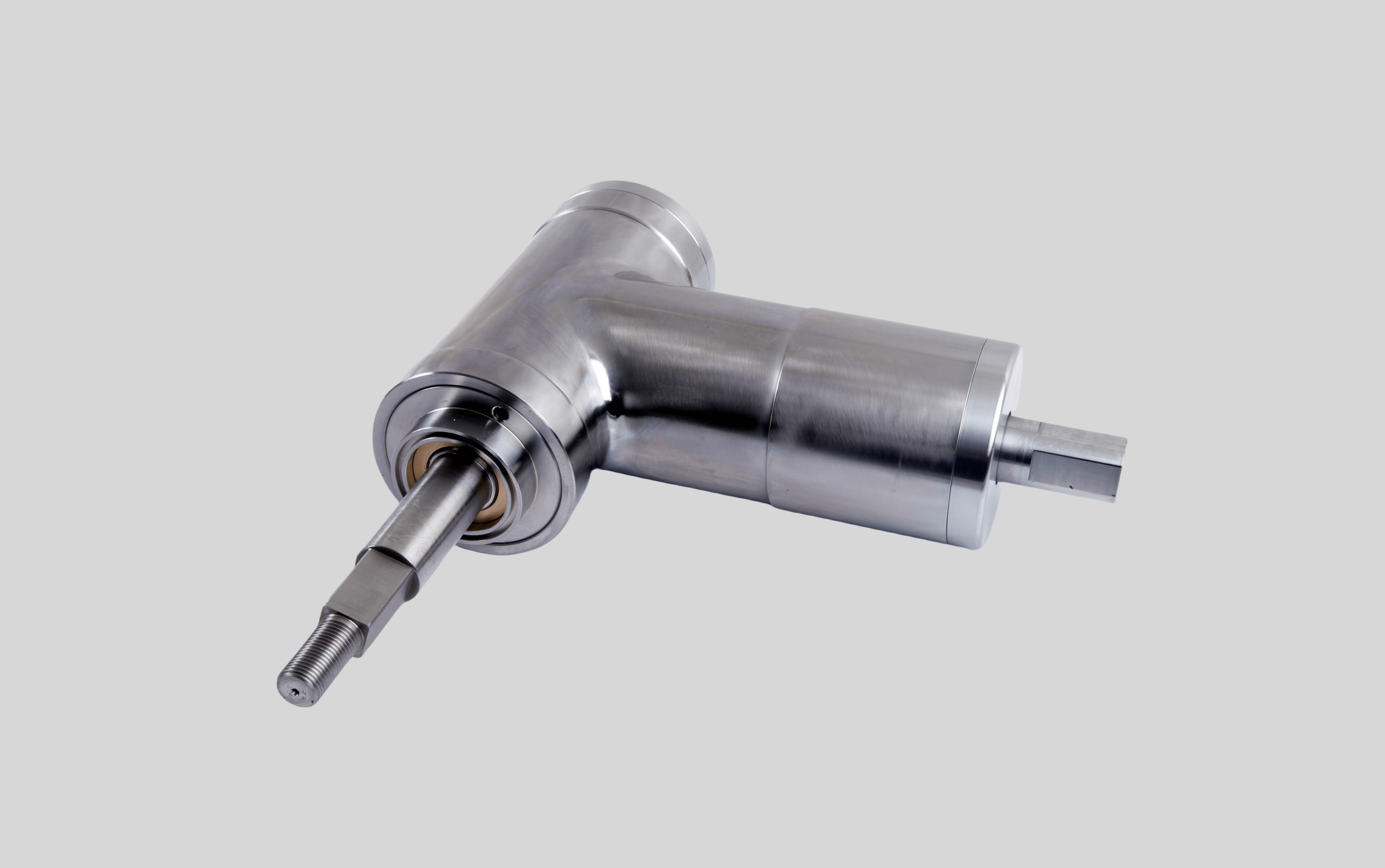

Mixing paddles & cutting knives

double-layer pot(insulated)

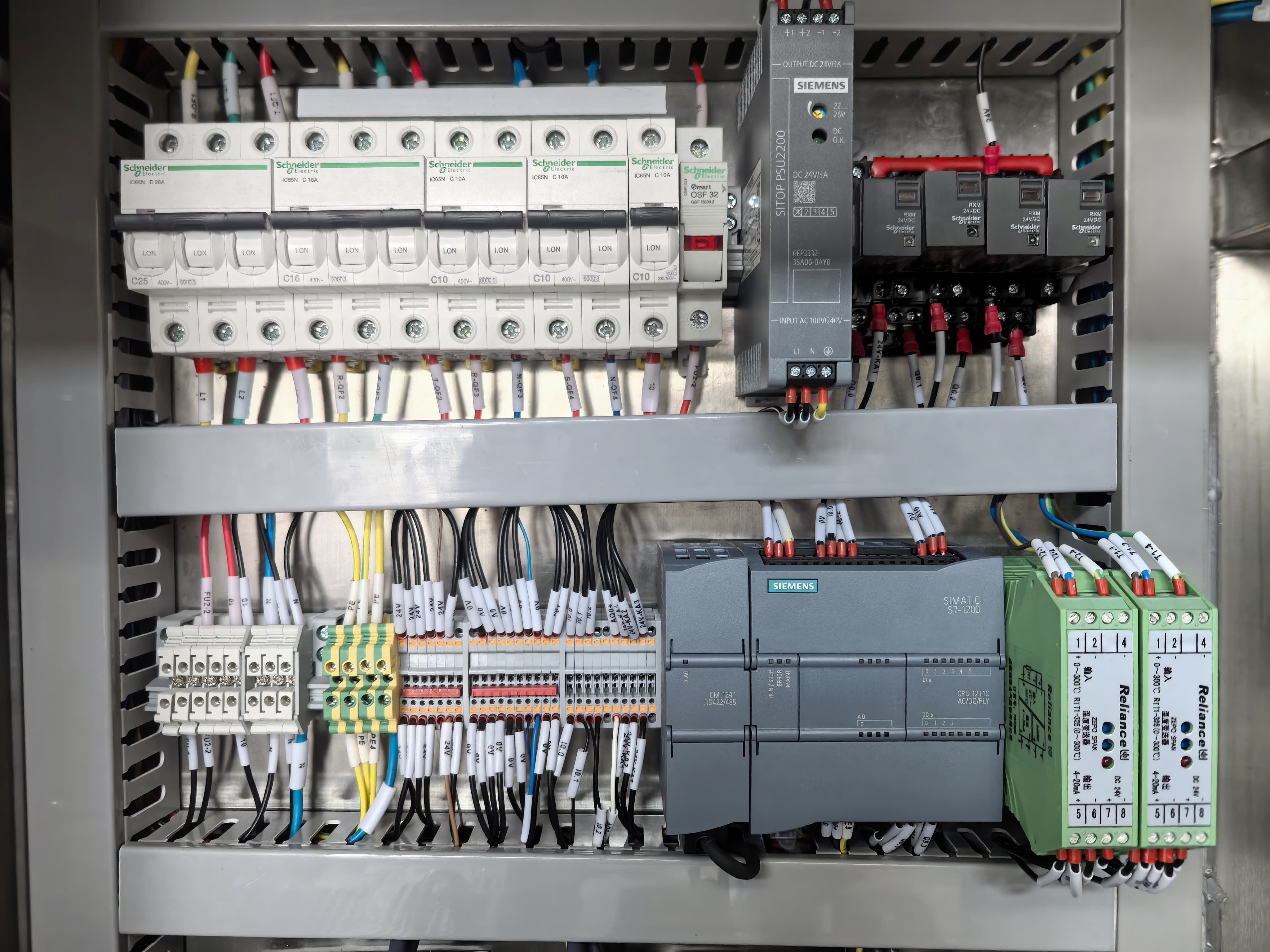

Siemens Touch Screen

electrical components

Pot changing cart

single layer pot

Mixing paddles & cutting knives

peristaltic pump

Item | Unit | model | ||||||||||||

VSG-0.5/1/2/4/6/10 | VSG-15/30/50 | VSG-100 | VSG-300 | VSG-600 | VSG-800 | |||||||||

volume | L | 0.5 | 1 | 2 | 4 | 6 | 10 | 15 | 30 | 50 | 100 | 350 | 600 | 800 |

Available capacity | L | 0.15-0.4 | 0.3-0.8 | 0.6-1.6 | 1.2-3.2 | 1.5-4.8 | 2.4-8 | 4.5-12 | 9.0-24 | 15-40 | 30-80 | 105-280 | 180-480 | 240-640 |

Batch range(bulk density 0.4) | kg/batch | 0.06-0.16 | 0.12-0.32 | 0.24-0.64 | 0.48-1.28 | 0.6-1.9 | 1-3.2 | 1.8-4.8 | 3.6-9.6 | 6-16 | 12-32 | 42-112 | 72-192 | 96-256 |

Motor power for stiring | r/min | 0-1000 | 60-600 | 25-250 | 5-160 | 4-150 | 5-145 | |||||||

speed of cutting knives | kw | 2 | 5.5 | 11 | 22 | 30 | 37 | |||||||

Motor power for cutting | rpm | 0-3000 | 200-3000 | 300-3000 | 300-3000 | 150-1500 | 150-1500 | |||||||

Compressed air pressure | kw | 0.4 | 1.5 | 7.5 | 7.5 | 11 | 11 | |||||||

power supply | MPa | ≥0.4 | ||||||||||||

Optional item | N/A | Wet legal grain pot body with sandwich + heating module+High active material OEB 4 / 5 | ||||||||||||

| installed capacity | V/Hz | 380V 50Hz | ||||||||||||

Due to equipment updates or upgrades, all the above data shall be subject to the final signed contract.

Prev

None

Next

More products

Pulverization of active pharmaceutical ingredients(APIs),including hard,crystalline,and fibrous materials,as well as materials requiring very fine particle size.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

By utilizing the high-speed relative motion between the rotor and the screen, agglomerated materials are rapidly granulated under the rotor’s compression, passing through the screen holes, with the finished granules discharged instantly.

Chongqing Liweikang's self-designed whole grain machine's right-angle transmission system and shaft sealing technology greatly reduces the risk of material contamination.

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 023-65663700

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Contact Information

Telephone

/ TEL

Address

/ ADD

No. 2, No. 712 Xiangfu Avenue, Shuangfu Street, jiangjin district, Chongqing

Scan mobile websites